Home » Case Products » Prototype Machined Parts: High-Precision Solutions for Advanced Design Testing

Prototype Machined Parts: High-Precision Solutions for Advanced Design Testing

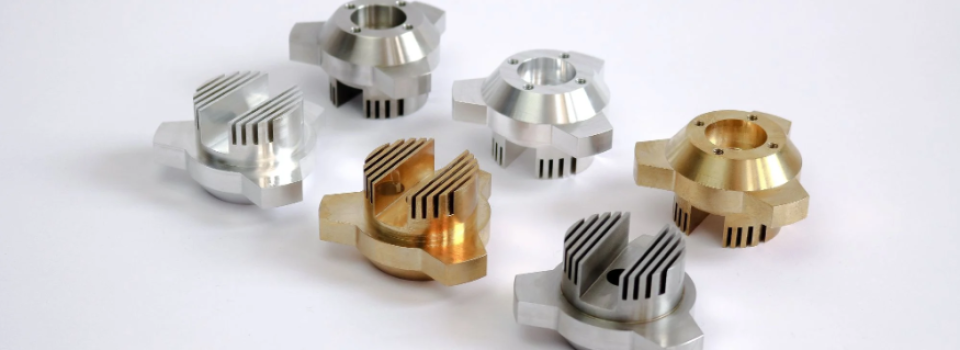

Unlock the potential of your designs with our prototype machined parts services. We specialize in creating high-precision, custom-machined components that are essential for evaluating functionality, performance, and design before moving to full-scale production. Ideal for industries such as aerospace, automotive, medical devices, and consumer products, our machined parts deliver the accuracy and durability needed for rigorous testing and validation.

Why choose our prototype machined parts services?

- Exceptional Precision: Utilizing advanced CNC machining technologies, we produce parts with tight tolerances and intricate details, ensuring that every prototype accurately reflects your design specifications.

- Durable and Functional: Our machined parts are crafted from high-quality materials, including metals and composites, providing the strength and durability needed for real-world testing and validation.

- Custom Fabrication: Tailored to your unique project requirements, from material selection to complex geometries, our services ensure that each part meets your specific functional and aesthetic needs.

- Rapid Production: Benefit from fast turnaround times, allowing for quick iterations and adjustments to accelerate your product development process and reduce time-to-market.

- Cost-Effective Testing: Identify and resolve design issues early in the prototyping phase, minimizing the risk of costly revisions during full-scale production and optimizing your development budget.

Enhance your product development with our expert prototype machined parts services. Contact us today to learn how we can help you achieve precise, durable prototypes that drive innovation and success.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Prototype Plastic Injection Molding: Precision Prototypes for Efficient Product Development

Read more -

Achieve Precision and Purity with Clean Room Injection Molding

Read more -

Your Go-To Partner Among Plastic Injection Molding Companies

Read more -

Quick Turn Prototyping: Fast, Reliable Solutions for Rapid Product Development

Read more -

Comprehensive Injection Molding Solutions for Your Business

Read more -

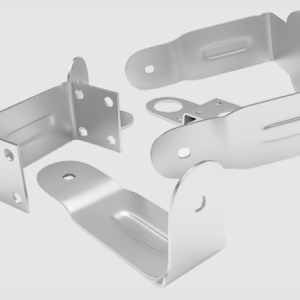

Prototype Sheet Metal Parts: Precision Engineering for Custom Metal Components

Read more