Home » Case Products » Micro Plastic Injection Molding

Micro Plastic Injection Molding

We specialize in producing high-quality, ultra-small plastic components using advanced micro molding techniques. Whether you need micro parts for medical devices, electronics, automotive, or other industries, we have the expertise and capabilities to meet your exact specifications.

Our Expertise:

- Advanced Technology: We utilize state-of-the-art micro injection molding machines and tooling to achieve exceptional precision and consistency in the production of micro parts. Our equipment is capable of handling extremely tight tolerances and intricate geometries.

- Material Expertise: We work with a wide range of engineering-grade thermoplastics suitable for micro molding, including ABS, PC, PEEK, POM, and more. Our material experts will help you select the best material for your application, considering factors such as strength, flexibility, and biocompatibility.

- Design Optimization: Our experienced team of engineers can assist with design optimization for micro parts, ensuring manufacturability while maintaining functionality and performance. We employ advanced simulation tools to analyze mold flow, minimize defects, and optimize part quality.

Key Features:

- Precision: Micro injection molding allows for the production of ultra-small parts with micron-level accuracy and consistency. Our process ensures tight dimensional control and minimal variation, making it ideal for applications that require precise fit and function.

- Complex Geometries: We specialize in molding micro parts with intricate features, such as microfluidic channels, micro-threads, and microstructures. Our advanced tooling capabilities enable us to replicate complex geometries with high fidelity and repeatability.

- Multi-Cavity Molding: To maximize efficiency and throughput, we utilize multi-cavity molds to produce multiple micro parts simultaneously. This approach reduces cycle times and lowers production costs while maintaining consistent quality across all parts.

Applications:

Our micro plastic injection molding solutions find applications in various industries, including:

- Medical Devices: Microfluidic components, catheter tips, surgical instruments, drug delivery systems.

- Electronics: Connectors, sensors, micro switches, miniature housings, microfluidic chips.

- Automotive: Micro gears, sensors, fuel injectors, connectors, miniature components.

- Consumer Electronics: Micro connectors, microphones, speakers, miniature housings, wearable devices.

- Aerospace: Micro valves, actuators, sensors, connectors, miniature components.

Benefits:

- Miniaturization: Micro molding enables the production of tiny components with complex features, allowing for miniaturization of devices and systems without compromising performance or reliability.

- Cost-Effectiveness: Despite the high precision and complexity involved, micro injection molding offers cost-effective solutions for producing large quantities of micro parts. It reduces material waste, labor costs, and secondary operations, resulting in overall cost savings.

- Time-to-Market: Our streamlined manufacturing process and rapid prototyping capabilities enable faster time-to-market for your products. We can quickly iterate designs, test concepts, and scale production to meet your project timelines.

Why Choose Us?

- Expertise: With years of experience in micro plastic injection molding, we have the knowledge, skills, and resources to tackle even the most challenging micro molding projects.

- Quality Assurance: We maintain rigorous quality control measures throughout the manufacturing process to ensure that each micro part meets the highest standards of precision, consistency, and reliability.

- Collaborative Partnership: We value collaboration and communication with our clients every step of the way. Our team will work closely with you to understand your requirements, address your concerns, and deliver solutions that exceed your expectations.

Partner with us for your micro plastic injection molding needs, and let us help you bring your most innovative ideas to life. Contact us today to discuss your project requirements or request a quote. We look forward to working with you!

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Innovate with Injection Foam Molding from DTG Injection Molding

Read more -

Rapid Sheetmetal: Fast, High-Quality Metal Prototyping and Fabrication

Read more -

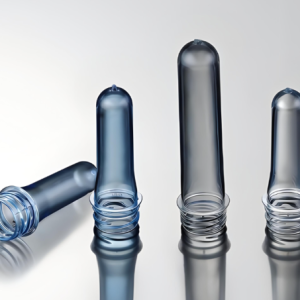

PET Injection Molding Solutions

Read more -

Plastic Injection Molding Parts

Read more -

Trusted Injection Molding Manufacturers: Quality and Precision for Your Projects

Read more -

Advanced Reaction Injection Molding (RIM) Services

Read more