Home » Case Products » Innovate with Injection Foam Molding from DTG Injection Molding

Innovate with Injection Foam Molding from DTG Injection Molding

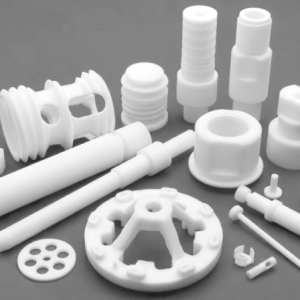

we specialize in injection foam molding, a cutting-edge process that combines the benefits of traditional injection molding with the advantages of foamed plastics. Our expertise and state-of-the-art technology ensure that you receive lightweight, durable, and high-quality components tailored to your specific needs.

Why Choose DTG Injection Molding for Injection Foam Molding?

1. Advanced Technology: Our advanced injection foam molding technology allows us to produce parts with a unique combination of strength, weight reduction, and material efficiency. This innovative process ensures high-performance components suitable for various applications.

2. Lightweight and Durable Parts: Injection foam molding produces parts that are significantly lighter than solid plastic parts without compromising on durability. This makes them ideal for applications where weight reduction is crucial, such as in the automotive, aerospace, and consumer goods industries.

3. Enhanced Material Properties: The foaming process enhances the material properties of the components, providing improved insulation, sound dampening, and impact resistance. These properties make injection foam molded parts suitable for a wide range of demanding environments.

4. Cost-Effective Solutions: By reducing material usage and cycle times, injection foam molding offers a cost-effective manufacturing solution. Our efficient production processes help you achieve your production goals while minimizing costs and maximizing profitability.

5. Complex Geometries: Our injection foam molding process allows for the creation of complex geometries and intricate designs. This flexibility ensures that your parts meet precise specifications and functional requirements.

6. Customization and Versatility: We provide tailored solutions to meet your unique requirements. Whether you need small, detailed components or large, complex structures, our team works closely with you to deliver custom injection foam molded parts that meet your exact needs.

7. Environmental Benefits: Injection foam molding reduces material waste and energy consumption, making it an environmentally friendly manufacturing option. Our commitment to sustainability ensures that your projects are produced with minimal environmental impact.

8. Comprehensive Support: From initial concept and design to final production and delivery, our team provides comprehensive support throughout your project. We offer expert guidance, technical assistance, and responsive customer service to ensure your complete satisfaction.

Experience the Advantages of Injection Foam Molding with DTG Injection Molding

Transform your production with our expert injection foam molding services. Contact DTG Injection Molding today to discuss your project and discover how our innovative solutions can enhance your products and reduce costs.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

High Precision Injection Molding

Read more -

OEM Plastic Black Parts Nylon Plastic Custom Service

Read more -

Car central control panel made by plastic injection mould

Read more -

Small Run Injection Molding: Cost-Effective Solutions for Low-Volume Production

Read more -

Plastic Prototype: Fast, Flexible, and Cost-Effective Prototyping Solutions

Read more -

Custom PVC/PP/PA66/POM Plastic Parts Moulded Injection Molding

Read more