Home » Case Products » Extrusion vs Injection Molding: Choosing the Right Manufacturing Process for Your Needs

Extrusion vs Injection Molding: Choosing the Right Manufacturing Process for Your Needs

At DTG Injection Molding, we understand that selecting the right manufacturing process is crucial for achieving optimal results. In this guide, we compare extrusion and injection molding to help you make an informed decision for your production needs.

Extrusion vs Injection Molding: A Comprehensive Comparison

Both extrusion and injection molding are widely used manufacturing processes with distinct advantages and applications. Understanding their differences can help you choose the best method for your project.

Key Differences Between Extrusion and Injection Molding

- Process Overview

- Extrusion: Material is melted and forced through a die to create long, continuous shapes. The material is then cooled and solidified as it exits the die.

- Injection Molding: Material is injected into a mold cavity under high pressure to create precise, complex shapes. The material cools and solidifies within the mold.

- Part Shapes and Complexity

- Extrusion: Ideal for producing long, uniform profiles such as pipes, tubing, and sheets. Best suited for simple cross-sectional shapes.

- Injection Molding: Capable of creating intricate and detailed parts with complex geometries. Suitable for both small and large production runs.

- Material Usage

- Extrusion: Typically uses thermoplastics and some thermosets. The process is continuous, which is efficient for high-volume production.

- Injection Molding: Can use a wide range of materials, including thermoplastics, thermosets, and elastomers. Ideal for high-precision and high-quality parts.

- Production Speed and Efficiency

- Extrusion: Continuous process that allows for high production speeds and lower costs for large quantities.

- Injection Molding: Suitable for high-volume production with quick cycle times. However, it may involve higher initial tooling costs.

- Tooling and Setup

- Extrusion: Requires a die specific to the desired shape. Tooling costs are relatively lower, but setup time can be longer for complex profiles.

- Injection Molding: Requires a custom mold, which can be expensive to design and produce. Setup is faster compared to extrusion for complex parts.

When to Choose Extrusion

- Applications: Ideal for manufacturing continuous profiles such as pipes, tubes, and window frames.

- Advantages: Cost-effective for large volumes, simple part shapes, and continuous production.

- Material Considerations: Best for thermoplastics and some thermosets.

When to Choose Injection Molding

- Applications: Suitable for intricate parts, complex geometries, and high-precision components such as automotive parts, medical devices, and consumer products.

- Advantages: High precision, ability to produce detailed features, and flexibility in material choices.

- Material Considerations: Suitable for a wide range of materials including high-performance thermoplastics and elastomers.

Our Services

- Expert Consultation

- Description: Our team provides expert advice to help you choose the most suitable manufacturing process for your specific needs.

- Applications: Design optimization, material selection, and process recommendations.

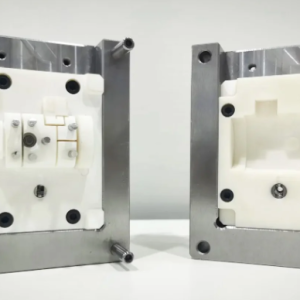

- Custom Tooling and Mold Design

- Description: We offer custom tooling and mold design services for both extrusion and injection molding processes.

- Applications: Tailored solutions to meet your production requirements and part specifications.

- Prototype and Production Runs

- Description: We provide rapid prototyping and full-scale production services for both extrusion and injection molding projects.

- Applications: Prototype development, design validation, and high-volume manufacturing.

- Quality Assurance

- Description: Comprehensive quality control processes ensure that every part meets your specifications and industry standards.

- Applications: Rigorous testing and inspection for consistent quality and performance.

Why Choose DTG Injection Molding?

- Industry Expertise: Our team has extensive experience in both extrusion and injection molding, offering tailored solutions for your needs.

- Advanced Technology: We utilize the latest technology and equipment to ensure high-quality results and efficient production.

- Custom Solutions: We provide customized services to meet your specific project requirements and goals.

- Competitive Pricing: Our cost-effective solutions deliver value without compromising on quality.

Get Started with Your Project

- Contact Us: Reach out via our online form, email, or phone to discuss your extrusion or injection molding project.

- Provide Your Details: Share your design files, material preferences, and production requirements.

- Receive a Quote: We’ll provide a detailed, competitive quote based on your specifications.

- Begin Production: Once approved, our team will start the production process, ensuring timely and high-quality results.

Connect with Us

Deciding between extrusion and injection molding? Contact DTG Injection Molding today to get expert advice and a prompt, accurate quote. Let us help you achieve the best results with our comprehensive manufacturing solutions.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Innovative 3D Printed Injection Mold Solutions

Read more -

OEM Custom Rubber PA66 Plastic Service Plastic Rapid Prototyping Parts

Read more -

PE Injection Molded Christmas Tree – Manufacturing Process

Read more -

Custom Solutions for Plastic Bobbins

Read more -

TPU Injection Molding Solutions

Read more -

High-Quality PETG Injection Molding Services from DTG Injection Molding

Read more