Home » Case Products » Achieve Superior Performance with Injection Molding Silicone Solutions

Achieve Superior Performance with Injection Molding Silicone Solutions

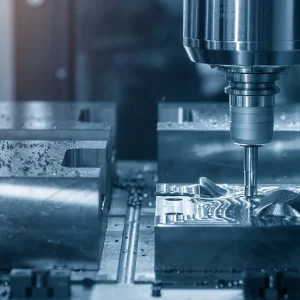

DTG Injection Molding offers specialized injection molding silicone services to meet the most demanding applications. Our expertise in silicone molding ensures you receive high-quality, durable, and precise parts for a wide range of industries.

Why Choose Our Injection Molding Silicone Services?

1. Exceptional Quality: Silicone is known for its excellent properties, including flexibility, heat resistance, and durability. Our injection molding silicone process guarantees parts that meet the highest quality standards, ensuring optimal performance in every application.

2. Versatile Applications: Silicone’s unique properties make it ideal for various applications, from medical devices to automotive components and consumer products. We provide tailored solutions to meet your specific needs, regardless of industry.

3. Precision and Accuracy: Our advanced molding technology ensures that every silicone part is produced with exceptional precision and consistency. We achieve tight tolerances and intricate designs, providing you with reliable and accurate components.

4. Custom Solutions: Whether you require standard parts or custom designs, our team of experts works closely with you to develop silicone molds that perfectly match your specifications. We offer comprehensive support from design to production.

5. Competitive Pricing: We offer cost-effective injection molding silicone services without compromising on quality. Our efficient production processes and economies of scale enable us to deliver top-quality parts at competitive prices.

Experience the Benefits of Silicone Molding with DTG Injection Molding

Enhance your products with the superior qualities of silicone. Choose DTG Injection Molding for your injection molding silicone needs and experience the difference in quality, performance, and service.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

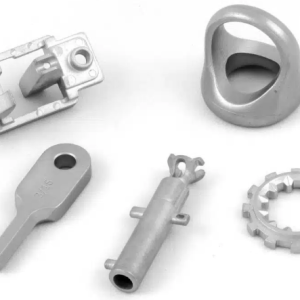

Transform Your Manufacturing with Metal Injection Molding

Read more -

Custom Plastic Injection Molding Waterproof Plastic Cover Durable Connector

Read more -

Custom Sizes Auto Part Solutions

Read more -

Powder Injection Molding

Read more -

Comprehensive Guide to Injection Molding Defects

Read more -

Leading Injection Mold Companies: Your Partner in Precision Manufacturing

Read more