Home » Case Products » Transform Your Manufacturing with Metal Injection Molding

Transform Your Manufacturing with Metal Injection Molding

At DTG Injection Molding, we specialize in metal injection molding (MIM), an advanced manufacturing process that combines the versatility of plastic injection molding with the strength and durability of metal. Our MIM services deliver high-quality, complex metal parts with unmatched precision and efficiency.

Why Choose DTG Injection Molding for Metal Injection Molding?

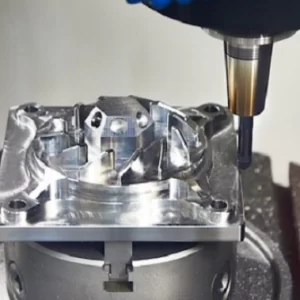

1. Superior Precision: Metal injection molding allows for the production of intricate and highly detailed parts that are difficult or impossible to achieve with traditional metalworking methods. Our advanced MIM technology ensures each part meets your exact specifications with exceptional precision.

2. High-Quality Materials: We use a wide range of metal powders, including stainless steel, titanium, and alloys, to produce parts that are strong, durable, and capable of withstanding demanding applications. Our material selection ensures that your components meet industry-specific requirements for performance and reliability.

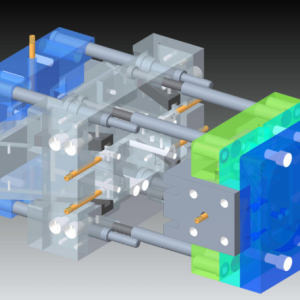

3. Complex Geometries: MIM is ideal for creating complex shapes and fine details that would be challenging and costly to produce using conventional machining. Our expertise in this process allows us to manufacture parts with sophisticated geometries and tight tolerances.

4. Cost-Effective Production: Metal injection molding combines the benefits of high-volume production with the strength of metal, making it a cost-effective solution for manufacturing complex parts. By reducing material waste and labor costs, we provide economical solutions without compromising quality.

5. Enhanced Mechanical Properties: Parts produced through MIM exhibit excellent mechanical properties, including high strength, hardness, and wear resistance. This makes them suitable for applications in automotive, aerospace, medical devices, and more.

6. Efficient Production: Our streamlined MIM processes allow for rapid production cycles, enabling us to deliver your parts quickly and efficiently. This ensures a faster time-to-market for your products, giving you a competitive edge.

7. Comprehensive Support: From initial design consultation to final production, our team of experts provides full support throughout your project. We offer guidance on material selection, design optimization, and process improvements to ensure your components meet the highest standards.

Experience the Advantages of Metal Injection Molding with DTG Injection Molding

Enhance your product designs and manufacturing efficiency with our expert metal injection molding services. Contact DTG Injection Molding today to discuss your project and discover how our MIM solutions can elevate your production.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Prototype CNC Machining: Precision Prototypes for Rapid Development

Read more -

Get Accurate Insights with Injection Molding Samples

Read more -

Silicone Plastic Injection Molding

Read more -

Polypropylene Plastic Injection Molding

Read more -

Elevate Your Products with Expert Mold Injection Design

Read more -

Injection Molded Plastic Toys

Read more