Yes, Polycarbonate (PC) can be dual injection molded with Acrylonitrile Butadiene Styrene (ABS). This process is known as two-shot or multi-shot injection molding, which allows for the combination of two different materials in a single molded part. PC/ABS blends are popular because they combine the strength and heat resistance of PC with the processability and toughness of ABS.

Key Considerations for Dual Injection Molding PC and ABS

1. Material Compatibility

- Adhesion: PC and ABS can bond well with each other during the molding process, creating a strong interface. This adhesion is essential for the structural integrity and performance of the final part.

- Thermal Properties: Both materials need to have compatible processing temperatures to ensure they can be molded in the same cycle without degrading either material.

2. Processing Temperatures

- Polycarbonate (PC): Typically requires higher processing temperatures, ranging from 270°C to 320°C.

- ABS: Has a lower processing temperature, usually between 200°C and 250°C.

[elementor-template id=”4330″]

3. Injection Molding Machine

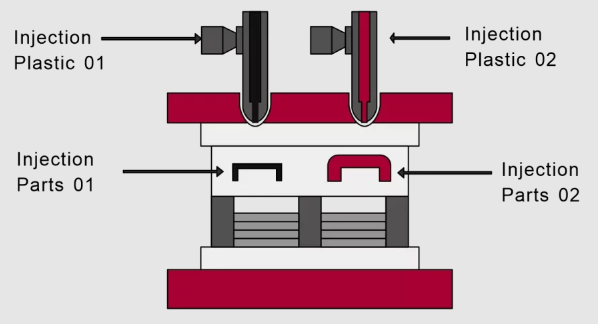

- Two-Shot Molding Machine: A specialized injection molding machine with two barrels and nozzles is used. This allows the machine to inject two different materials in a single cycle.

- Sequential Injection: The machine must precisely control the sequence and timing of the injection process to ensure proper adhesion and part quality.

4. Mold Design

- Complex Mold Structure: The mold must be designed to accommodate the two materials, often with separate cavities or core designs that allow for the sequential injection.

- Gating and Flow Paths: Proper design of gating systems and flow paths ensures that each material flows correctly into its designated areas without interference.

Advantages of Dual Injection Molding PC and ABS

1. Enhanced Properties

- Mechanical Strength: Combining PC’s strength and rigidity with ABS’s impact resistance results in parts with superior mechanical properties.

- Aesthetic Flexibility: Allows for different colors and surface finishes in a single part, enhancing design possibilities.

2. Cost Efficiency

- Integrated Production: Dual injection molding reduces assembly time and costs by producing complex, multi-material parts in a single molding cycle.

- Material Utilization: Optimizes the use of materials, reducing waste compared to separate molding and assembly processes.

3. Functional Integration

- Complex Part Design: Enables the creation of parts with integrated functions, such as combining a rigid structural component (PC) with a flexible or resilient component (ABS).

[elementor-template id=”4331″]

Applications

1. Automotive Parts

- Interior Components: Dashboards, handles, and trim parts where a combination of rigidity and toughness is needed.

- Exterior Components: Mirror housings and other parts that require a durable yet aesthetically pleasing finish.

2. Consumer Electronics

- Housings: Mobile phone cases, laptop covers, and other electronic device housings that benefit from the mechanical properties and aesthetic appeal.

- Connectors and Buttons: Parts that need both structural integrity and tactile responsiveness.

3. Medical Devices

- Instrument Housings: Combining the durability of PC with the ease of processing and sterilization-friendly nature of ABS.

References

- Plastics Technology: Detailed insights into the dual injection molding process and material considerations.

- DuPont – Material Compatibility: Discusses the compatibility and benefits of PC/ABS blends.

- Injection Molding of Polymers: Overview of the injection molding process and materials.

Dual injection molding of PC and ABS offers a versatile and efficient manufacturing solution, combining the best properties of both materials for a wide range of applications.

Related Conten: Plastic Blow Molding

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|