Yes, HDPE (High-Density Polyethylene) can be injection molded. HDPE is a popular thermoplastic polymer known for its high strength-to-density ratio, excellent impact resistance, and chemical stability, making it suitable for a wide range of applications in injection molding. Here’s a detailed look at HDPE injection molding:

Properties of HDPE

- High Strength-to-Density Ratio: HDPE is strong and lightweight.

- Chemical Resistance: Resistant to many solvents, acids, and bases.

- Impact Resistance: Durable and can withstand significant impact without breaking.

- Low Moisture Absorption: Minimal water absorption, maintaining mechanical properties in moist environments.

- Good Insulating Properties: Effective electrical insulator.

[elementor-template id=”4330″]

Applications of HDPE Injection Molding

- Packaging:

- Bottles and Containers: Commonly used for milk, detergent, and other liquid containers.

- Caps and Lids: Durable caps and closures for bottles and jars.

- Consumer Goods:

- Household Items: Storage bins, food containers, and kitchenware.

- Toys: Lightweight and durable toys.

- Industrial Applications:

- Pipes and Fittings: Used in plumbing and irrigation systems due to its resistance to chemicals and pressure.

- Cable Insulation: Electrical cable insulation and other protective covers.

- Automotive Parts:

- Fuel Tanks: Due to its chemical resistance and durability.

- Interior Components: Various interior trims and protective covers.

- Medical Devices:

- Containers and Trays: Used in medical packaging and storage solutions.

Injection Molding Process for HDPE

- Material Preparation:

- HDPE pellets are dried if necessary to remove any moisture, though HDPE typically has low moisture absorption.

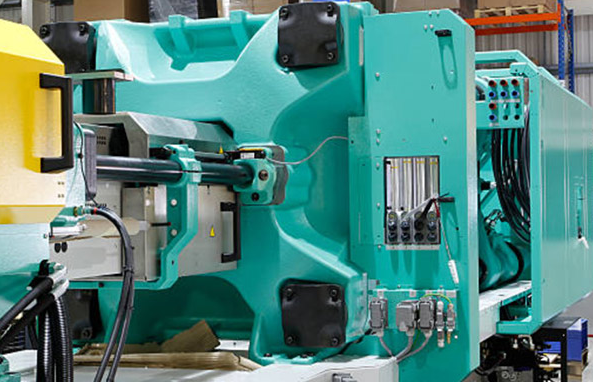

- Injection Molding Machine Setup:

- Temperature Settings: Barrel temperatures are usually set between 180°C to 230°C (356°F to 446°F).

- Mold Temperature: Typically maintained between 20°C to 80°C (68°F to 176°F).

- Injection Pressure: Adjusted based on part design, typically between 700 to 1500 psi.

- Cooling Time: Adequate cooling time is essential to prevent warpage and ensure part integrity.

- Molding Cycle:

- Injection: Molten HDPE is injected into the mold cavity at high pressure.

- Cooling: The part cools and solidifies in the mold. Cooling time depends on part thickness and mold temperature.

- Ejection: Once solidified, the part is ejected from the mold.

- Post-Processing:

- Parts may undergo trimming to remove any excess material or flash.

- Additional finishing processes, such as printing or assembly, may be applied.

[elementor-template id=”4331″]

Benefits of Using HDPE in Injection Molding

- Cost-Effective: HDPE is relatively inexpensive compared to other engineering plastics.

- Versatility: Can be used for a wide range of applications due to its favorable properties.

- Ease of Processing: HDPE flows well and is relatively easy to mold, reducing cycle times and manufacturing costs.

- Recyclability: HDPE is recyclable, making it an environmentally friendly option.

Considerations

- Shrinkage: HDPE has relatively high shrinkage rates (1.5% to 4%), which must be considered in mold design to ensure accurate part dimensions.

- Warpage: Proper cooling and mold design are essential to minimize warpage, especially in thicker parts.

Conclusion

HDPE is an excellent material for injection molding due to its favorable properties, ease of processing, and versatility. It is widely used across various industries for applications that require strength, durability, and chemical resistance. Proper machine setup, mold design, and processing conditions are crucial to achieving high-quality HDPE injection-molded parts.

Related Conten: Plastic Assembly Decoration

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|