Injection molding inspection reports are critical documents used to ensure that molded parts meet specified quality standards and customer requirements. These reports detail various aspects of the molding process, dimensional accuracy, material properties, and overall part quality. Here are the key components and types of standard injection molding inspection reports:

1. First Article Inspection (FAI) Report

Purpose:

- To verify that the initial samples of a new or revised part meet all design specifications and quality requirements before mass production.

Components:

- Part Identification: Part number, revision level, description.

- Material Certification: Verification of the material used.

- Dimensional Measurements: Comparison of actual dimensions to specified tolerances.

- Visual Inspection: Checking for surface finish, color, and appearance.

- Functional Tests: Ensuring the part functions as intended.

- Documentation: Including drawings, specifications, and any changes made.

Importance:

- Ensures that the production process is capable of producing parts that meet quality standards.

- Identifies any issues early, reducing the risk of defects in mass production.

[elementor-template id=”4330″]

2. In-Process Inspection Report

Purpose:

- To monitor and control the quality of parts during the production process.

Components:

- Process Parameters: Temperature, pressure, cycle time, and other relevant molding parameters.

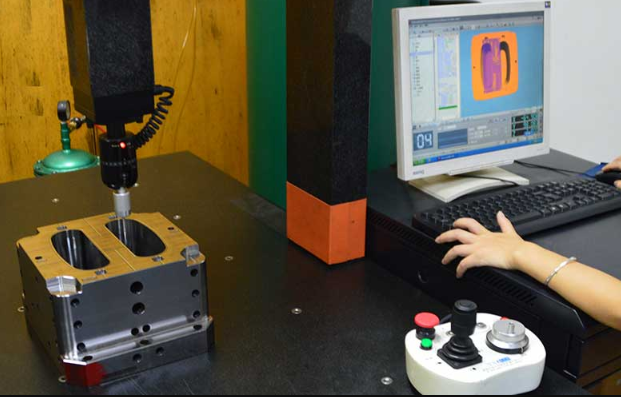

- Dimensional Checks: Regular measurements of critical dimensions.

- Visual Inspections: Ongoing checks for cosmetic defects.

- Sampling Plan: Frequency and sample size for inspections.

Importance:

- Helps in detecting and addressing issues in real-time, ensuring consistent quality.

- Reduces the likelihood of producing large quantities of defective parts.

3. Final Inspection Report

Purpose:

- To ensure that finished parts meet all quality requirements before shipment to the customer.

Components:

- Complete Dimensional Analysis: Final verification of all critical dimensions.

- Visual Inspection: Detailed check for surface finish, color, and appearance.

- Functional Testing: Ensuring parts perform their intended function.

- Packaging Inspection: Verifying proper packaging and labeling.

Importance:

- Ensures that only parts that meet all quality standards are shipped to customers.

- Helps in maintaining customer satisfaction and trust.

4. Material Verification Report

Purpose:

- To confirm that the materials used in production meet specified requirements.

Components:

- Material Type and Grade: Verification of the correct plastic resin.

- Material Properties: Checking properties such as tensile strength, hardness, and melt flow index.

- Supplier Certifications: Documentation from material suppliers.

Importance:

- Ensures the correct materials are used, which is crucial for part performance and durability.

- Prevents potential failures due to incorrect or substandard materials.

[elementor-template id=”4331″]

5. Capability Study Report

Purpose:

- To assess the process capability and ensure it can consistently produce parts within specified tolerances.

Components:

- Cp and Cpk Values: Statistical measures of process capability.

- Process Stability: Analysis of process variation over time.

- Histogram and Control Charts: Visual representation of process performance.

Importance:

- Identifies process variations and potential improvements.

- Ensures consistent quality in mass production.

6. Defect Analysis Report

Purpose:

- To analyze and document defects found in the molded parts.

Components:

- Defect Description: Detailed description and classification of defects.

- Root Cause Analysis: Investigation into the causes of defects.

- Corrective Actions: Steps taken to address and prevent defects.

- Inspection Results: Data from additional inspections after corrective actions.

Importance:

- Helps in understanding and eliminating the root causes of defects.

- Improves overall process quality and efficiency.

Conclusion

Standard injection molding inspection reports are essential tools for ensuring product quality and process consistency. By systematically documenting and analyzing various aspects of the production process and part quality, manufacturers can identify and address issues early, maintain high standards, and meet customer requirements. Regular use of these reports helps in continuous improvement, leading to more efficient production and higher-quality products.

Related Conten: Rapid Injection Molding

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|