Injection molding is a highly efficient manufacturing process, but it can be prone to various defects that affect the quality and performance of the final product. Understanding these potential defects and their causes is crucial for preventing them and ensuring high-quality production. Here are some common defects encountered in injection molding and their potential causes:

1. Warping

Warping occurs when different parts of a molded object shrink unevenly, leading to deformation.

- Causes:

- Uneven cooling rates across the part

- Non-uniform wall thickness

- Improper mold design

- Material properties and filler content

- Prevention:

- Ensure uniform wall thickness

- Optimize cooling rates and mold temperature

- Use materials with lower shrinkage rates

[elementor-template id=”4330″]

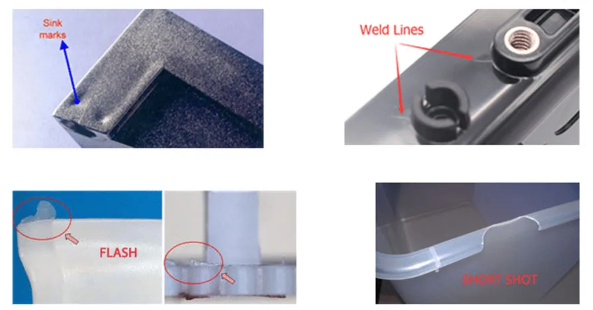

2. Sink Marks

Sink marks are small depressions that appear on the surface of the part due to uneven cooling and shrinkage.

- Causes:

- Insufficient packing pressure

- Thick sections cooling slower than thin sections

- Improper gate location

- Prevention:

- Increase packing pressure and time

- Design uniform wall thickness

- Optimize gate location and size

3. Flash

Flash is excess material that flows out of the mold cavity and forms a thin layer on the part’s surface.

- Causes:

- Mold clamping force is too low

- Worn or damaged mold components

- Excessive injection pressure

- Prevention:

- Increase clamping force

- Regular maintenance of mold components

- Reduce injection pressure

4. Burn Marks

Burn marks are discolorations or dark spots on the surface of the molded part, usually caused by trapped air or overheating.

- Causes:

- Trapped air or gas in the mold cavity

- Excessive injection speed or temperature

- Poor venting in the mold

- Prevention:

- Improve mold venting

- Reduce injection speed and temperature

- Ensure proper material drying

[elementor-template id=”4331″]

5. Short Shots

Short shots occur when the mold cavity is not completely filled, resulting in an incomplete part.

- Causes:

- Insufficient material injection

- Low injection pressure or speed

- Blocked or undersized gates and runners

- Prevention:

- Increase injection pressure and speed

- Ensure proper gate and runner design

- Use adequate shot size

6. Flow Lines

Flow lines are visible streaks or patterns on the surface of the part caused by variations in the flow of molten material.

- Causes:

- Variations in injection speed or temperature

- Improper gate location

- Mold temperature differences

- Prevention:

- Optimize injection speed and temperature

- Place gates in locations that promote uniform flow

- Ensure consistent mold temperature

7. Weld Lines

Weld lines are visible lines or marks where two flow fronts meet, leading to weak points in the part.

- Causes:

- Multiple gates or complex part geometry

- Insufficient material temperature or injection speed

- Poor mold design

- Prevention:

- Optimize material temperature and injection speed

- Redesign mold to minimize flow front convergence

- Use appropriate gating locations

8. Voids

Voids are small pockets of air trapped within the molded part, leading to weak spots and structural defects.

- Causes:

- Insufficient packing pressure

- Excessive material shrinkage

- Poor mold venting

- Prevention:

- Increase packing pressure and time

- Use materials with lower shrinkage rates

- Improve mold venting

[elementor-template id=”4330″]

9. Delamination

Delamination occurs when thin layers of material separate from the part, often appearing as peeling or flaking.

- Causes:

- Contaminated material

- Incompatible materials used together

- Excessive moisture in the material

- Prevention:

- Ensure material purity and compatibility

- Properly dry the material before molding

- Use appropriate processing conditions

10. Brittleness

Brittleness refers to parts that are prone to breaking or cracking under stress.

- Causes:

- Poor material selection

- Overheating or underheating of material

- Inadequate cooling time

- Prevention:

- Choose appropriate materials with desired mechanical properties

- Optimize processing temperatures

- Allow sufficient cooling time

Conclusion

Injection molding defects can significantly impact the quality and functionality of the final product. By understanding the causes and implementing preventative measures, manufacturers can minimize defects, improve product quality, and increase production efficiency. Proper mold design, material selection, and process optimization are key factors in achieving defect-free injection-molded parts.

Related Conten: https://www.m-dtg.com/service/prototype-injection-molding/

DTG Mould Trade Process |

|

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

|

|