Home » Case Products » Metal Injection Molding Services

Metal Injection Molding Services

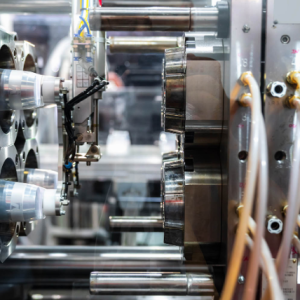

Our Metal Injection Molding (MIM) services, where we specialize in producing high-quality, precision-molded metal components. MIM combines the design flexibility of plastic injection molding with the mechanical properties of metal, offering a cost-effective solution for manufacturing complex, high-performance parts. Our expertise ensures that you receive reliable, durable, and customized metal components tailored to your specific needs.

Key Features:

- Material Properties: MIM enables the use of a variety of metals, including stainless steel, titanium, copper, and nickel alloys, providing exceptional strength, wear resistance, and thermal stability.

- Precision and Consistency: Advanced injection molding techniques and state-of-the-art machinery ensure precise dimensions, tight tolerances, and consistent quality across all production runs.

- Complex Geometries: MIM allows for the creation of intricate designs and complex shapes that would be challenging or costly to produce using traditional metalworking methods.

- Customization: We offer tailored solutions, including custom part design, material selection, and surface finishes, to meet your unique requirements.

Applications:

Our Metal Injection Molding solutions cater to a wide range of industries and applications, including:

- Aerospace: High-performance components such as turbine blades, fasteners, and structural parts that require superior strength and precision.

- Automotive: Durable and wear-resistant parts for engines, fuel systems, and safety components.

- Medical Devices: Biocompatible and precision-engineered components for surgical instruments, orthodontic appliances, and implantable devices.

- Electronics: High-precision components such as connectors, heat sinks, and sensor housings that demand excellent thermal and electrical properties.

- Industrial: Robust parts for machinery, tools, and equipment used in demanding environments.

Benefits:

- High Mechanical Strength: MIM parts offer excellent mechanical properties, including high tensile strength, hardness, and wear resistance, making them suitable for demanding applications.

- Cost-Effective Production: MIM combines the efficiency of plastic injection molding with the performance of metal, reducing manufacturing costs and material waste.

- Design Flexibility: MIM allows for the production of complex shapes and fine details, providing greater design freedom and reducing the need for secondary operations.

- Material Versatility: MIM supports a wide range of metals and alloys, enabling the production of parts with specific mechanical, thermal, and electrical properties.

Why Choose Us?

- Expertise: With extensive experience in metal injection molding, we possess the technical knowledge and practical skills to deliver high-quality components that meet your specific requirements.

- Advanced Technology: Our state-of-the-art injection molding machines and tooling are optimized for processing metal powders, ensuring precision, consistency, and efficiency in every production run.

- Quality Assurance: We implement stringent quality control protocols throughout the manufacturing process, from material selection to final inspection, ensuring that every part meets the highest standards of quality.

- Customer-Centric Approach: We work closely with our clients to understand their unique requirements and provide tailored solutions that enhance the functionality, performance, and marketability of their products.

Partner with Us:

Partner with us for your Metal Injection Molding needs, and let us help you create high-quality, durable, and precision-engineered metal components that excel in your industry. Contact us today to discuss your project requirements or request a quote. We look forward to working with you!

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

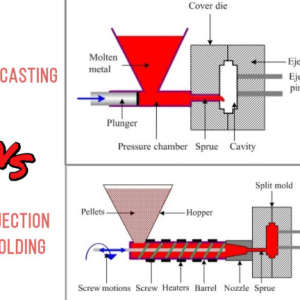

Die Casting vs. Injection Molding: Which Manufacturing Process is Right for You?

Read more -

Understanding the Rubber Injection Molding Process: A Comprehensive Guide

Read more -

Micro Plastic Injection Molding

Read more -

Custom Injection Molding Companies: Tailored Solutions for Your Unique Needs

Read more -

Injection Mold Company: Your Partner in Precision Manufacturing

Read more -

Structural Foam Injection Molding: Strength and Efficiency Combined

Read more