Home » Case Products » Master Injection Molding Knit Lines with DTG Injection Molding

Master Injection Molding Knit Lines with DTG Injection Molding

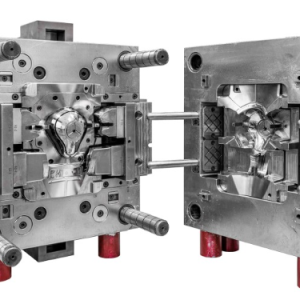

we understand that knit lines—also known as weld lines or flow lines—can be a significant challenge in the injection molding process. Our expertise and advanced technology ensure that we effectively manage and minimize knit lines, resulting in high-quality, structurally sound, and aesthetically pleasing parts.

Why Choose DTG Injection Molding for Managing Injection Molding Knit Lines?

1. Advanced Analysis and Simulation: We use state-of-the-art simulation software to predict and analyze the formation of knit lines during the design phase. This proactive approach allows us to optimize mold design and injection parameters to minimize knit lines before production begins.

2. Expert Design Optimization: Our team of experts works closely with you to optimize part and mold design, focusing on gate placement, flow paths, and material selection. These optimizations are crucial in reducing knit lines and enhancing the overall quality of the molded parts.

3. Precision Molding Techniques: We employ precise molding techniques and advanced machinery to control the molding process parameters, such as temperature, pressure, and injection speed. This level of control helps in minimizing the occurrence of knit lines and ensures consistent quality.

4. High-Quality Materials: The selection of the right materials is critical in managing knit lines. We provide guidance on the best materials to use for your specific application, considering factors such as flow properties, cooling rates, and compatibility with the injection molding process.

5. Rigorous Quality Control: Our rigorous quality control procedures include thorough inspection and testing to identify and address any knit line issues. We ensure that every part meets the highest standards of structural integrity and appearance.

6. Customized Solutions: We offer customized solutions tailored to your specific needs. Whether you need parts with complex geometries or high aesthetic requirements, our team works to deliver injection molded parts with minimal knit lines and maximum performance.

7. Cost-Effective Production: By effectively managing knit lines, we reduce the need for rework and reject rates, resulting in cost-effective production. Our efficient processes help you save time and money while maintaining high-quality standards.

8. Comprehensive Support: From initial consultation and design optimization to final production and delivery, our team provides comprehensive support throughout your project. We offer expert advice, technical assistance, and dedicated customer service to ensure your complete satisfaction.

Achieve Superior Quality with DTG Injection Molding’s Knit Line Management

Overcome the challenges of injection molding knit lines with our expert solutions. Contact DTG Injection Molding today to discuss your project and discover how we can help you achieve superior quality parts with minimal knit lines.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Comprehensive Injection Molding Solutions for Your Business

Read more -

China Factory OEM/ODM Customized Rapid Prototype Mould Manufacturer Plastics Parts for Molded Parts

Read more -

Get Accurate and Competitive Injection Mold Quotes with DTG Injection Molding

Read more -

Custom ABS Plastic Cover Plastic Mold Window Regulator Button

Read more -

Top Injection Mold Manufacturers: Your Partner for Precision and Quality

Read more -

EVA Injection Molding Solutions

Read more