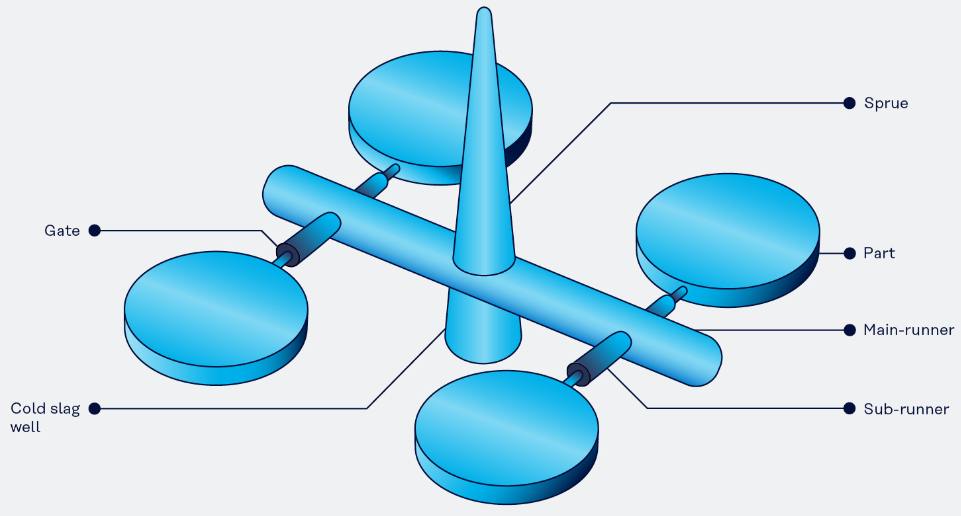

In injection molding, a sprue is the primary channel through which molten plastic flows from the injection molding machine’s nozzle…

2024

In injection molding, shrinkage refers to the reduction in size or dimensions of a plastic part as it cools and…

In injection molding, shear rate refers to the rate at which the material flows and experiences deformation within the mold…

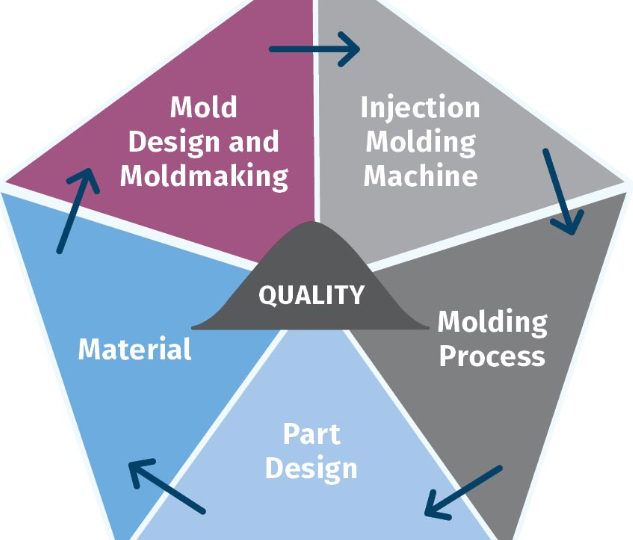

Scientific Injection Molding (SIM), also known as Decoupled Molding, is an advanced injection molding technique that emphasizes the use of…

A runner in injection molding is a channel that guides the molten plastic from the injection molding machine’s nozzle to…

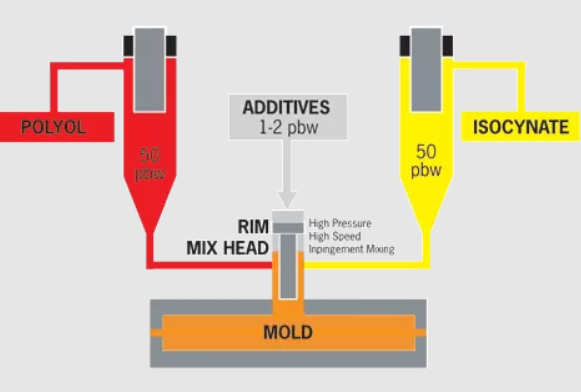

Reaction Injection Molding (RIM) is a manufacturing process used to produce molded plastic parts by mixing two or more liquid…

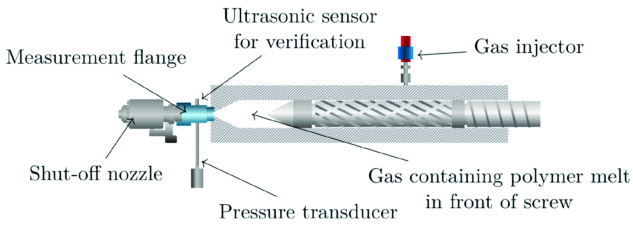

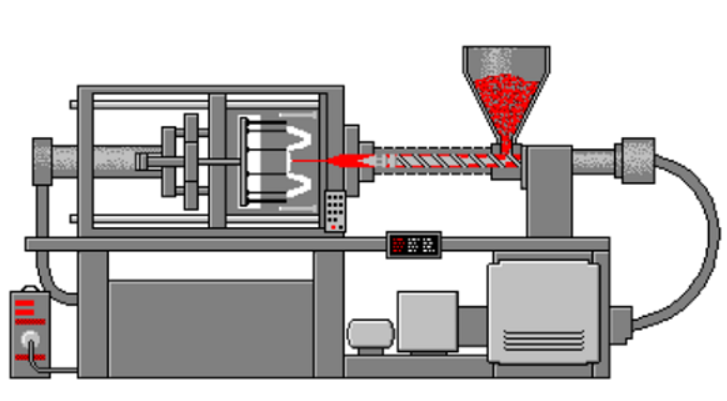

Plasticizing in injection molding is a crucial phase where solid plastic pellets are transformed into a homogeneous molten state, making…

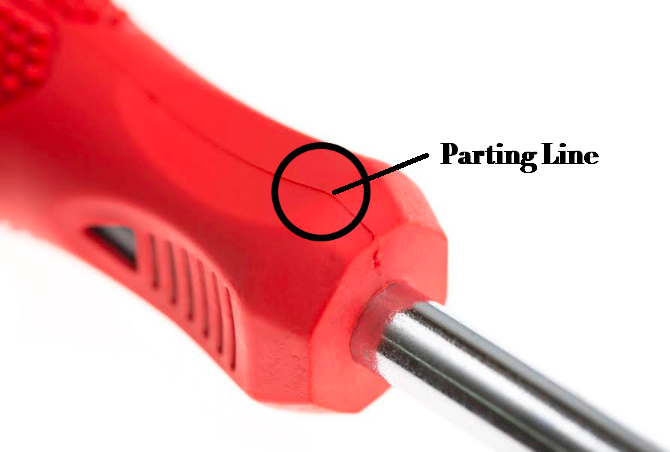

A parting line in injection molding is the line or plane where two or more parts of the mold meet….

Packing pressure in injection molding refers to the pressure applied to the molten plastic after the initial cavity filling phase….

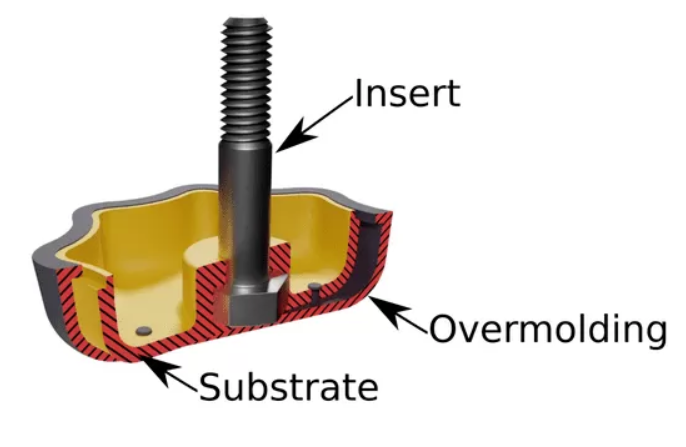

Overmolding is a specialized injection molding process used to create multi-material parts, combining two or more different materials into a…