Achieving optimal validation in injection molding involves ensuring that the molded parts meet all specified requirements and quality standards throughout…

2024

Achieving a matte finish in injection molding involves several techniques, primarily focusing on the mold surface texture, material selection, and…

olycarbonate is a versatile and widely used thermoplastic known for its strength, impact resistance, and transparency. When it comes to…

Injection molding of rubber can achieve very thin parts, but the exact minimum thickness depends on several factors including the…

3D printing a plastic injection mold can be a cost-effective and rapid way to prototype and produce small batches of…

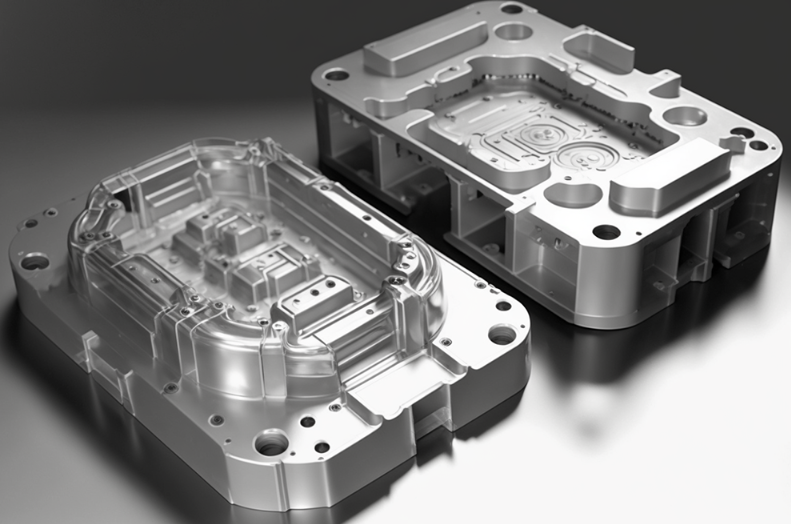

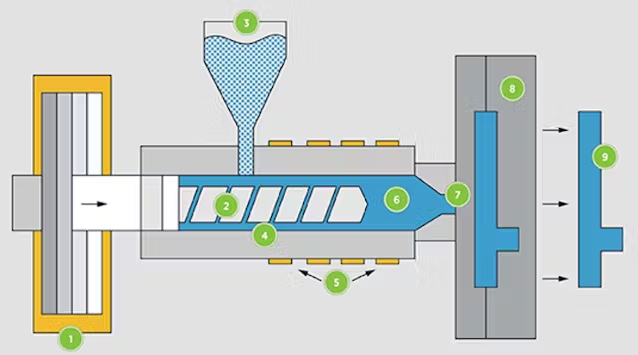

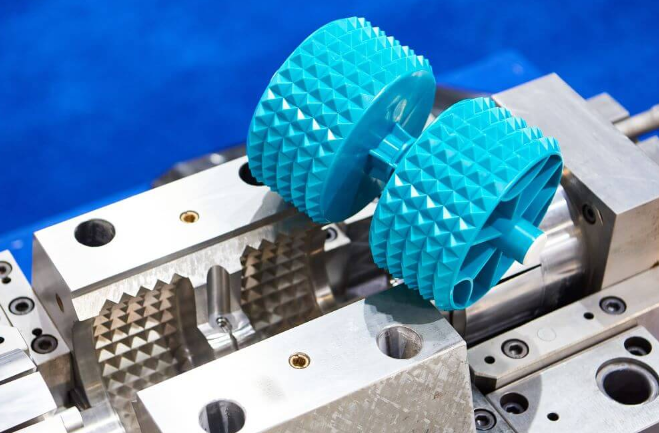

Plastic injection molding is a widely used manufacturing process for producing plastic parts. It involves injecting molten plastic material into…

The strength of injection-molded gun parts compared to milled steel parts varies significantly due to the inherent differences in material…

Injection molded plastic can vary widely in strength depending on the type of plastic used, the part design, and the…

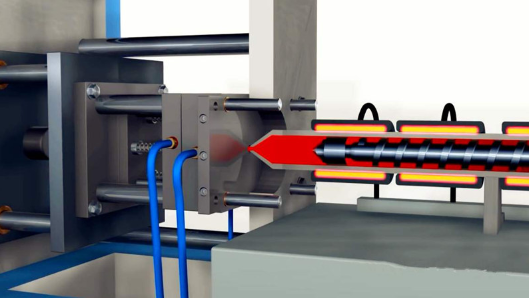

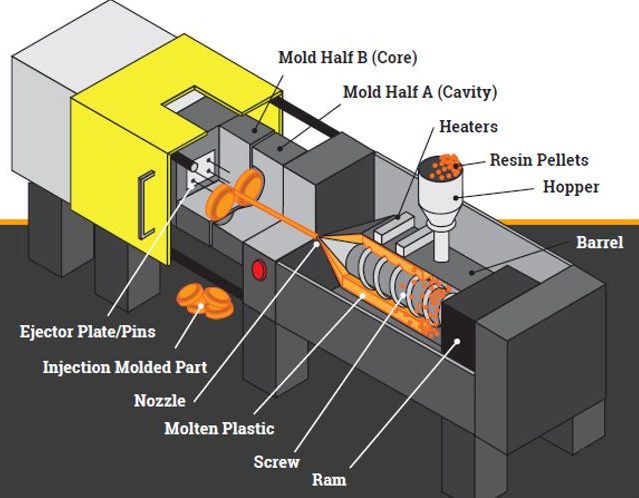

Plastic injection molding machines are complex pieces of equipment that transform raw plastic material into finished products through a series…

The cycle time of an injection molding process refers to the time it takes to complete one full sequence of…