日期: 2024 年 7 月 7 日

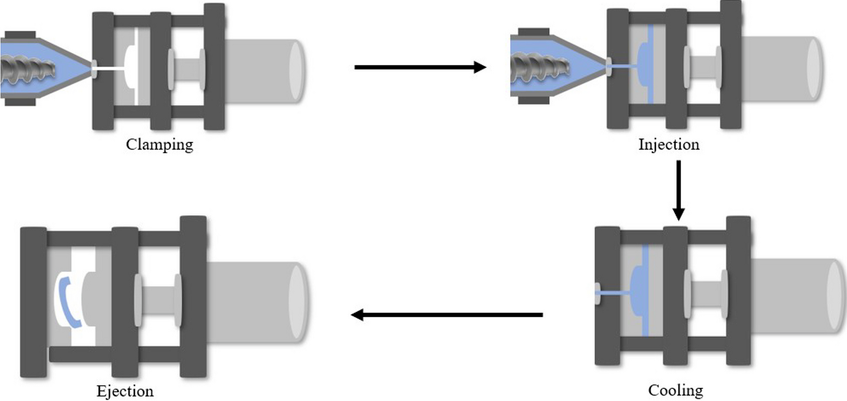

What Are Slider Lines On Injection Mold?

Overview Slider lines on injection molds are marks or l … 阅读更多

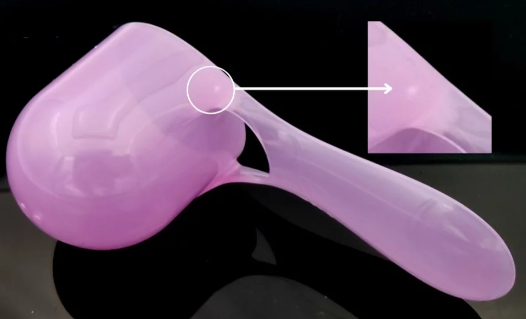

What Are Sink Marks In Injection Molded Components?

Sink marks are surface depressions or indentations that … 阅读更多

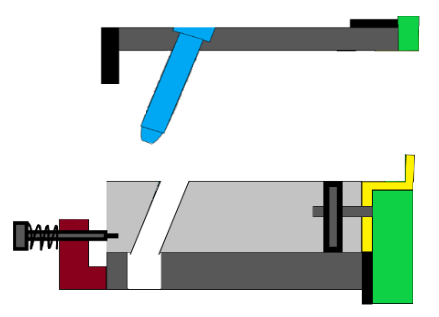

Is High Sprue Pressure Desirable In Injection Molding?

Advantages of High Sprue Pressure Disadvantages of High … 阅读更多

Is Flexible Tubing Extruded Or Injection Molded?

Flexible tubing is typically produced using extrusion r … 阅读更多

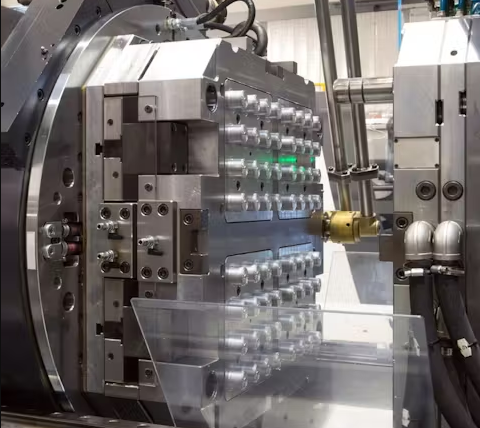

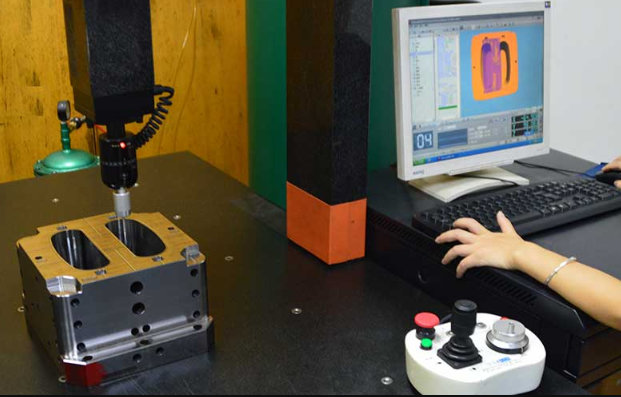

Standard Injection Molding Inspection Reports

Injection molding inspection reports are critical docum … 阅读更多