Home » Case Products » Plastic Injection Molding Medical Parts

Plastic Injection Molding Medical Parts

We specialize in producing high-quality, precision-engineered plastic components for the medical industry using advanced molding techniques. Our expertise ensures that you receive parts that meet stringent medical standards for safety, reliability, and performance.

Our Expertise:

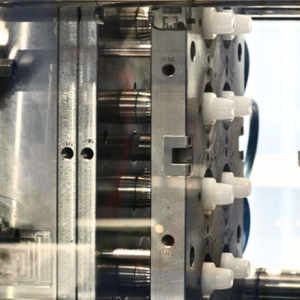

- Advanced Technology: We utilize state-of-the-art injection molding machines and specialized tooling to produce medical-grade plastic parts with exceptional precision and consistency.

- Material Selection: We work with a variety of medical-grade thermoplastics, including ABS, PC, PP, PE, PEEK, and more, chosen for their biocompatibility, sterilization compatibility, and mechanical properties.

- Regulatory Compliance: Our manufacturing processes adhere to strict regulatory standards, including ISO 13485 for medical devices, ensuring that our parts meet the highest quality and safety requirements.

Key Features:

- Biocompatibility: Our medical-grade plastics are biocompatible and suitable for direct contact with the human body, making them ideal for a wide range of medical applications.

- Sterilization Compatibility: Plastic parts produced through our injection molding processes can withstand various sterilization methods, including autoclaving, gamma radiation, and ethylene oxide (EtO) sterilization.

- Precision and Consistency: We maintain tight tolerances and stringent quality control measures to ensure that every medical part meets the exact specifications required for its intended use.

Applications:

Our plastic injection molding services for medical parts cover a wide range of applications, including:

- Surgical Instruments: Handles, trays, forceps, and other precision components.

- Diagnostic Equipment: Housings, covers, and components for diagnostic devices.

- Drug Delivery Systems: Inhalers, syringe components, and drug delivery devices.

- Implantable Devices: Enclosures, connectors, and components for implantable medical devices.

- Laboratory Equipment: Vials, test tubes, pipettes, and other laboratory consumables.

Benefits:

- Safety and Compliance: Our medical-grade plastic parts meet regulatory requirements, ensuring safety and compliance with industry standards.

- Reliability and Performance: Precision engineering and stringent quality control measures ensure that our medical parts deliver reliable performance in critical medical applications.

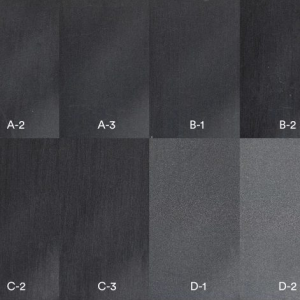

- Customization: We offer customization options to meet specific design requirements, including material selection, color matching, and surface finishes.

Why Choose Us?

- Expertise and Experience: With extensive experience in plastic injection molding for the medical industry, we have the knowledge and capabilities to deliver high-quality medical parts that meet your exact specifications.

- Quality Assurance: We adhere to strict quality management systems, including ISO 13485 certification, to ensure that every part meets the highest standards of quality and reliability.

- Customer Focus: We prioritize customer satisfaction and work closely with our clients to understand their unique requirements, providing tailored solutions that exceed expectations.

Explore our plastic injection molding capabilities for medical parts and discover how we can help you bring your medical device innovations to life. Contact us today to discuss your project requirements or request a quote. We look forward to partnering with you to advance healthcare solutions with high-quality plastic components.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Your Go-To Partner Among Plastic Injection Molding Companies

Read more -

Injection Molding Finishes: Enhance the Quality and Aesthetics of Your Parts

Read more -

Understanding and Preventing Injection Molding Flash

Read more -

Complex Injection Molding Services

Read more -

ABS Injection Molding Services

Read more -

Factory Insert for Custom Plastic Parts

Read more