Home » Case Products » Plastic Chair Injection Mold

Plastic Chair Injection Mold

Welcome to our plastic chair injection mold manufacturing service, where we specialize in producing high-quality molds for manufacturing plastic chairs. With our expertise in mold design, precision engineering, and advanced manufacturing techniques, we ensure that your plastic chairs are produced efficiently, reliably, and with exceptional quality.

Key Features of Our Plastic Chair Injection Molds:

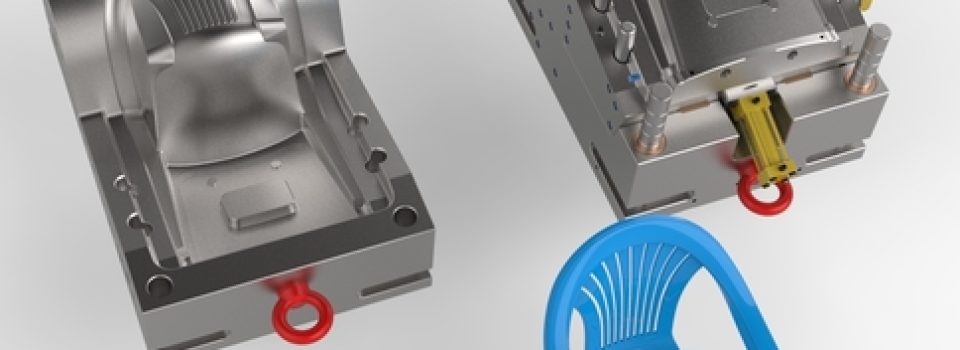

- Custom Design: We offer custom mold design services tailored to your specific chair design requirements. Whether you need stackable chairs, armchairs, or ergonomic designs, our team of experienced designers can create molds that meet your exact specifications.

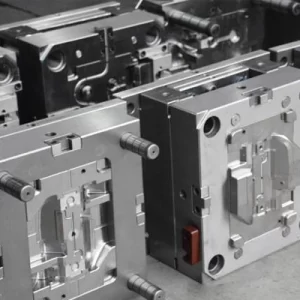

- High-Quality Materials: We use premium-grade steel and aluminum alloys to manufacture our injection molds, ensuring durability, longevity, and resistance to wear and corrosion.

- Precision Engineering: Our molds are machined with the latest CNC (Computer Numerical Control) technology to achieve precise dimensions, intricate details, and smooth surface finishes.

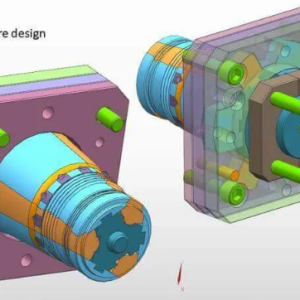

- Optimized Cooling System: Efficient cooling channels are integrated into the mold design to ensure rapid and uniform cooling of the plastic material, reducing cycle times and improving productivity.

- Multi-Cavity Molds: To maximize production efficiency, we offer multi-cavity molds capable of producing multiple chair components simultaneously, increasing output and reducing per-unit costs.

- Ease of Use: Our molds are designed for ease of use and maintenance, with features such as quick-change inserts, interchangeable components, and accessible mold cavities for easy cleaning and maintenance.

Production Process:

- Mold Design: Our experienced engineers work closely with you to understand your chair design requirements and develop a customized mold design that meets your specifications.

- Mold Manufacturing: Using advanced CNC machining and EDM (Electrical Discharge Machining) processes, we manufacture the mold components with precision and accuracy.

- Assembly and Testing: The mold components are assembled and rigorously tested to ensure proper fit, function, and performance before being delivered to the production facility.

- Injection Molding Production: Once the mold is installed in the injection molding machine, the plastic material is injected into the mold cavities, where it takes the shape of the chair components.

- Demolding and Finishing: After cooling, the molded chair components are ejected from the mold, inspected for quality, and finished as needed, including trimming excess material, smoothing edges, and adding surface treatments.

- Assembly and Packaging: The finished chair components are assembled into complete chairs, inspected for quality, and packaged for shipping to customers.

Benefits of Our Plastic Chair Injection Molds:

- High-Quality Production: Our molds ensure consistent, high-quality production of plastic chairs with precise dimensions, smooth surface finishes, and excellent structural integrity.

- Efficiency and Productivity: With optimized cooling systems and multi-cavity designs, our molds enable efficient production processes, reducing cycle times and increasing output.

- Cost-Effectiveness: By maximizing production efficiency and minimizing material waste, our molds help lower production costs and improve overall profitability.

- Customization Options: We offer flexibility in mold design to accommodate various chair designs, sizes, colors, and features, allowing for customization to meet specific customer needs.

Why Choose Us:

- Expertise: With years of experience in mold design and manufacturing, we have the knowledge, skills, and resources to deliver high-quality plastic chair injection molds that meet the most demanding requirements.

- Quality Assurance: We adhere to strict quality control standards throughout the manufacturing process to ensure that every mold meets the highest standards of quality, reliability, and performance.

- Customer Satisfaction: We prioritize customer satisfaction and strive to exceed expectations by providing personalized service, timely communication, and innovative solutions that meet our customers’ needs and objectives.

Partner with us for your plastic chair injection mold manufacturing needs, and let us help you create high-quality chairs that meet your design, performance, and production requirements. Contact us today to discuss your project requirements or request a quote. We look forward to working with you!

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Custom Metal Fabrication Prototype: Precision Prototyping for Advanced Product Development

Read more -

Custom Plastic Injection Molding for Auto Courtesy Light Warning Lamps

Read more -

Expert Injection Mold Making Services for Precision and Efficiency

Read more -

High-Quality Injection Molding Parts from DTG Injection Molding

Read more -

Injection Molding Soft Plastic Lures

Read more -

Achieve Excellence with Expert Injection Molding Design

Read more