Home » Case Products » High-Quality Molds for Plastic Injection: Precision and Reliability

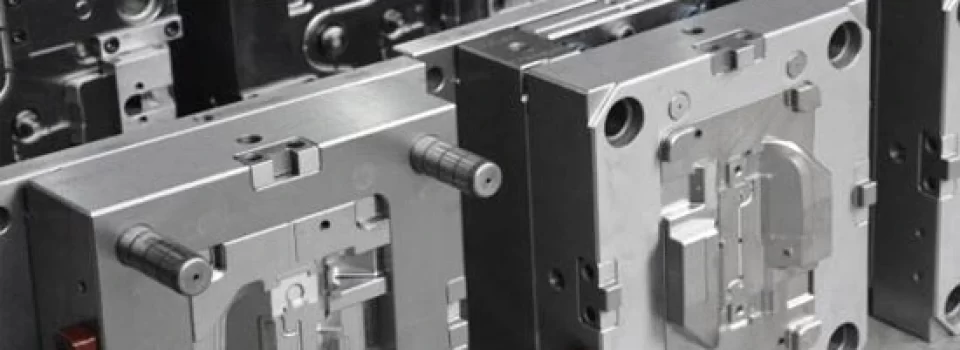

High-Quality Molds for Plastic Injection: Precision and Reliability

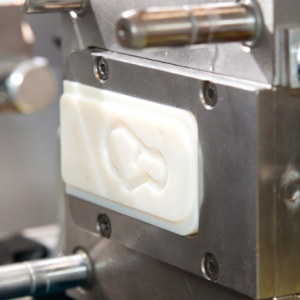

In the world of manufacturing, having the right molds for plastic injection is essential for producing high-quality parts with consistency and efficiency. At DTG injection molding, we specialize in designing and manufacturing superior plastic injection molds tailored to your specific needs. Learn why we are the preferred choice for businesses seeking reliable and precise injection mold solutions.

Why Choose Our Molds for Plastic Injection?

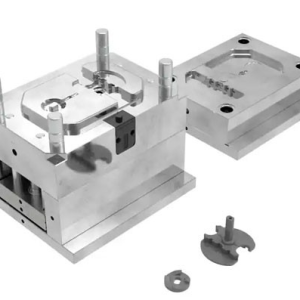

- Advanced Design and Engineering: Our molds are designed using the latest CAD/CAM software, ensuring precision and optimal performance. Our engineering team works closely with you to develop molds that meet your exact specifications and requirements.

- Durable Materials: We use high-grade materials, including hardened tool steel and stainless steel, to manufacture our molds. This guarantees longevity, strength, and reliability, even under high production volumes.

- Customization: Every project is unique, and we offer customized mold solutions to match your specific needs. From complex geometries to intricate details, our custom molds ensure your products meet the highest standards.

- Rigorous Quality Control: Quality is our top priority. We implement stringent quality control measures throughout the design and manufacturing process to ensure each mold meets the highest standards of accuracy and performance.

- Cost Efficiency: Our molds are designed for efficiency, reducing cycle times and material waste. This results in cost savings and improved productivity for your injection molding operations.

Our Molds for Plastic Injection

- Prototype Molds: Ideal for testing and validating new designs, our prototype molds allow you to make adjustments before full-scale production.

- Production Molds: Built for high-volume production, our molds ensure consistent quality and durability throughout the manufacturing process.

- Insert Molds: Perfect for overmolding and insert molding applications, providing flexibility in combining different materials.

- Multi-Cavity Molds: Designed to produce multiple parts per cycle, our multi-cavity molds increase efficiency and reduce production costs.

Industries We Serve

- Automotive: Precision molds for producing components such as dashboard parts, bumpers, and engine covers.

- Medical: High-quality molds for medical devices, surgical instruments, and diagnostic equipment.

- Consumer Goods: Durable molds for a variety of consumer products, including electronics, toys, and household items.

- Aerospace: Robust molds for manufacturing lightweight and high-strength aerospace components.

Contact Us for Superior Plastic Injection Molds

Ready to enhance your production with high-quality molds for plastic injection? Contact us today to discuss your project requirements and receive a personalized quote. Our dedicated team is committed to delivering exceptional molds that meet your needs.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

3D Printer Injection Molding: Combining Additive Manufacturing with Precision Molding for Innovative Solutions

Read more -

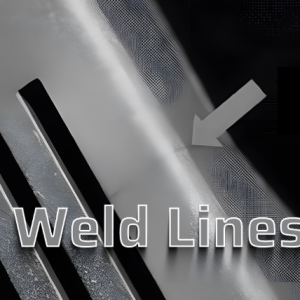

Optimize Your Production with Expert Weld Line Injection Molding Solutions

Read more -

Flow Lines in Injection Molding

Read more -

Premium Custom Injection Mold Services

Read more -

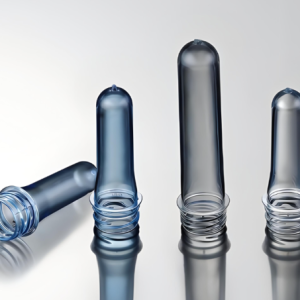

PET Injection Molding Solutions

Read more -

ABS Injection Molding Services

Read more