Home » Case Products » High-Quality Metal Injection Molds at DTG Injection Molding

High-Quality Metal Injection Molds at DTG Injection Molding

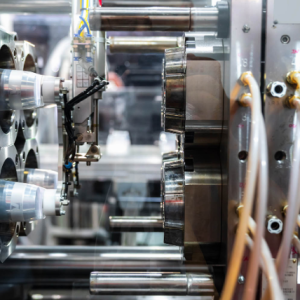

At DTG Injection Molding, we offer top-tier metal injection mold services to produce high-precision, durable metal parts for a variety of applications. Our state-of-the-art technology and expert team ensure that each mold meets the highest standards of quality and performance.

What is Metal Injection Molding?

Metal injection molding (MIM) is a process that combines the benefits of injection molding with the properties of metal. Fine metal powders are mixed with a binder to create a feedstock, which is then injected into molds to produce intricate and high-strength metal parts. After molding, the binder is removed, and the metal is sintered to achieve the final product.

Advantages of Metal Injection Molding

- Complex Geometries

- Description: MIM allows for the production of complex and detailed parts that are difficult or impossible to achieve with traditional metalworking methods.

- Benefits: Ideal for parts with intricate designs, thin walls, and high precision.

- High Material Density

- Description: The sintering process produces parts with high material density and superior mechanical properties.

- Benefits: Enhanced strength, durability, and performance.

- Cost Efficiency

- Description: MIM reduces material waste and manufacturing costs compared to other metalworking techniques.

- Benefits: Economical production, especially for high-volume runs.

- Consistent Quality

- Description: Advanced molding techniques ensure uniform quality and dimensional accuracy across all produced parts.

- Benefits: Reliable and repeatable production outcomes.

Our Metal Injection Mold Services

- Custom Mold Design

- Description: We provide custom mold design services tailored to meet your specific requirements and ensure optimal performance.

- Applications: Automotive components, aerospace parts, consumer electronics, and more.

- Precision Manufacturing

- Description: Our advanced manufacturing capabilities ensure high precision and accuracy in every metal injection mold.

- Applications: Complex parts with tight tolerances and intricate details.

- Material Expertise

- Description: We work with a variety of metal powders, including stainless steel, titanium, and cobalt-chrome, to achieve the desired properties for your parts.

- Applications: Parts requiring specific mechanical, thermal, or corrosion-resistant characteristics.

- Prototyping and Production

- Description: We offer prototyping services to validate designs before full-scale production, ensuring that your final molds meet all specifications.

- Applications: Product development, design verification, and high-volume manufacturing.

Why Choose DTG Injection Molding?

- Advanced Technology: Our state-of-the-art MIM technology and precision tools ensure high-quality molds and parts.

- Experienced Team: Our skilled engineers and technicians bring extensive experience in metal injection molding and mold design.

- Quality Assurance: Rigorous quality control processes ensure that every part meets your exact specifications and industry standards.

- Cost-Effective Solutions: We offer competitive pricing and efficient production processes to deliver cost-effective solutions without compromising on quality.

Industries We Serve

- Automotive: High-strength components for engines, transmissions, and other automotive systems.

- Aerospace: Precision parts for aircraft and spacecraft, including structural components and fasteners.

- Consumer Electronics: Durable and high-performance parts for electronic devices and accessories.

- Medical Devices: Components for medical instruments, implants, and diagnostic equipment.

- Industrial Equipment: Robust parts for machinery, tools, and industrial applications.

How to Get Started with Your Metal Injection Mold Project

- Contact Us: Reach out to us via our online form, email, or phone to discuss your project requirements.

- Provide Specifications: Share your design files, material preferences, and molding requirements with our team.

- Receive a Quote: We will review your project details and provide a detailed, competitive quote within 24 hours.

- Project Execution: Upon approval, our team will begin the design and production process, ensuring timely and high-quality delivery.

Contact Us Today

Ready to achieve superior results with expert metal injection molding? Contact DTG Injection Molding today to discuss your requirements and receive a fast, accurate quote. Let us help you produce high-quality metal parts with our expert molding services.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

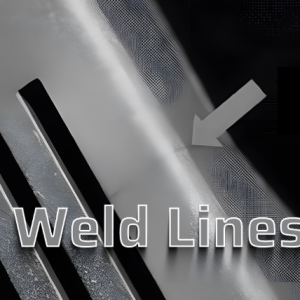

Optimize Your Production with Expert Weld Line Injection Molding Solutions

Read more -

Metal Injection Molding in China: Precision and Efficiency for Your Metal Parts

Read more -

Maximize Efficiency and Precision with Injection Molding Automation

Read more -

Understanding the Rubber Injection Molding Process: A Comprehensive Guide

Read more -

Precision Medical Device Injection Molding Services at DTG Injection Molding

Read more -

Explore Our Custom Plastic Pokéballs – Plastic Molding

Read more