Home » Case Products » Expert Solutions for Injection Molding Gates

Expert Solutions for Injection Molding Gates

The design and placement of injection molding gates are critical factors that influence the quality and performance of molded parts. At DTG Injection Molding, we specialize in optimizing gate design and placement to ensure superior results for all your injection molding projects.

What is an Injection Molding Gate?

An injection molding gate is the entry point where molten plastic flows from the runner system into the mold cavity. The gate’s design, size, and location can significantly impact the part’s appearance, structural integrity, and overall quality.

Types of Injection Molding Gates

- Edge Gate

- Description: Positioned on the edge of the part, commonly used for flat or thin parts.

- Benefits: Simple design, easy to manufacture, and suitable for various applications.

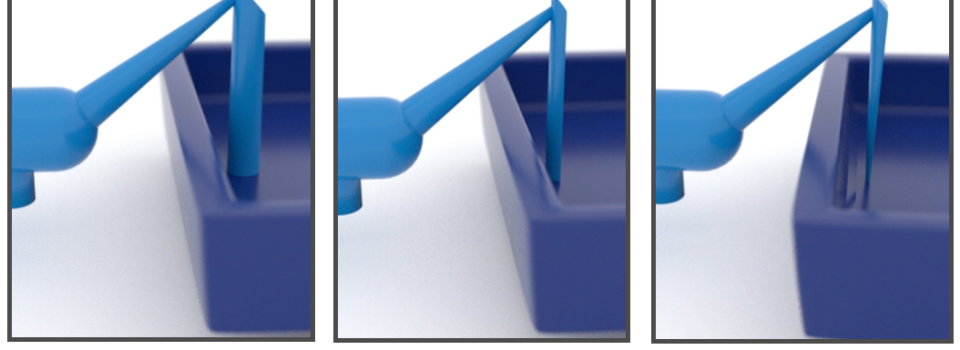

- Submarine Gate (Tunnel Gate)

- Description: Positioned below the parting line, allows automatic degating.

- Benefits: Reduces post-molding operations, minimizes gate vestige.

- Pin Gate

- Description: Small, round gate typically used in multi-cavity molds.

- Benefits: Uniform material flow, minimal gate marks, suitable for small parts.

- Fan Gate

- Description: Spreads the molten plastic in a fan shape to fill wide areas.

- Benefits: Reduces flow lines and warping, ideal for large, flat parts.

- Diaphragm Gate

- Description: Circular gate used for cylindrical or tubular parts.

- Benefits: Ensures even material distribution, reduces weld lines.

Importance of Gate Design and Placement

- Flow Control: Proper gate design and placement ensure even material flow, reducing the risk of defects such as warping and sink marks.

- Structural Integrity: Optimized gating helps maintain the part’s strength and durability by minimizing stress concentrations and weld lines.

- Aesthetic Quality: Well-designed gates minimize visible marks and defects, enhancing the part’s appearance.

- Cycle Time Efficiency: Efficient gating can reduce cycle times and improve production efficiency, lowering overall costs.

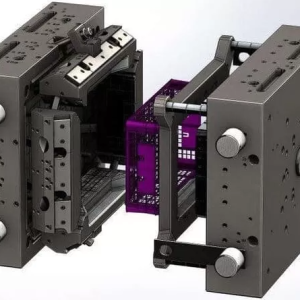

DTG Injection Molding’s Approach to Gate Optimization

- Advanced Simulation: We use advanced simulation software to analyze material flow and optimize gate design and placement for each project.

- Expert Engineering: Our experienced engineers apply their extensive knowledge to design gates that meet the specific needs of your part and application.

- Precision Manufacturing: Using state-of-the-art equipment, we ensure precise gate creation and placement for optimal performance.

- Quality Assurance: Rigorous quality control processes at every stage of production ensure that gates function as intended and produce high-quality parts.

Why Choose DTG Injection Molding for Gate Design?

- Custom Solutions: We provide tailored gate design solutions to meet the unique requirements of each project.

- High Quality: Our focus on precision and quality ensures that your parts meet the highest standards of performance and appearance.

- Cost Efficiency: Optimized gate design and placement reduce waste, cycle times, and production costs.

- Customer Satisfaction: We prioritize your satisfaction and work closely with you to ensure your expectations are met and exceeded.

Get Started with Optimized Gate Design

- Contact Us: Reach out to us via our online form, email, or phone to discuss your project requirements.

- Provide Specifications: Share your design files, material preferences, and expected quantity with our team.

- Receive a Quote: We will review your project details and provide a detailed, competitive quote within 24 hours.

- Project Execution: Upon approval, our team will begin the design and production process, ensuring timely and high-quality delivery.

Contact Us Today

Ready to optimize your injection molding gate design and enhance the quality of your parts? Contact DTG Injection Molding today to discuss your requirements and receive a fast, accurate quote. Let us help you achieve superior injection molding results with our expert services.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

PTFE Injection Molding Solutions

Read more -

Your Premier Partner for Injection Mold in China

Read more -

Lexan Injection Molding

Read more -

Optimize Your Budget with Transparent Custom Injection Molding Cost

Read more -

Polyethylene Injection Molding

Read more -

Small Scale Plastic Injection Molding

Read more