Home » Case Products » Hemp Plastic Injection Molding

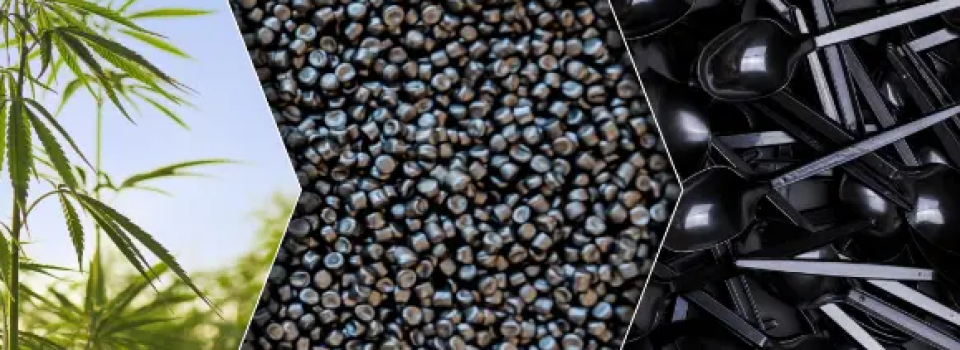

Hemp Plastic Injection Molding

We specialize in producing eco-friendly plastic components using hemp-filled materials. With our expertise in sustainable manufacturing and advanced injection molding techniques, we offer high-quality, biodegradable alternatives to traditional plastics.

Our Expertise:

- Hemp-Filled Materials: We work with hemp-filled plastics, which combine hemp fibers or hemp-derived materials with thermoplastics to create biocomposite materials suitable for injection molding.

- Material Development: Our team collaborates with material suppliers to develop custom formulations optimized for injection molding processes, ensuring excellent flow properties, mechanical strength, and biodegradability.

- Injection Molding Techniques: We utilize specialized equipment and tooling designed for processing hemp-filled materials, enabling precise and efficient molding of eco-friendly plastic components.

Key Features:

- Sustainability: Hemp plastic offers a sustainable alternative to traditional petroleum-based plastics, as hemp is a renewable resource that requires minimal water and pesticides to cultivate.

- Biodegradability: Hemp-filled plastics are biodegradable and compostable, reducing environmental impact and contributing to circular economy initiatives.

- Mechanical Properties: Hemp fibers enhance the mechanical properties of plastic materials, providing improved strength, stiffness, and impact resistance compared to unfilled plastics.

Applications:

Our hemp plastic injection molding services are suitable for various applications, including:

- Packaging: Biodegradable packaging materials, trays, and containers.

- Consumer Goods: Eco-friendly products such as toys, utensils, and household items.

- Automotive: Interior components, panels, and trim pieces.

- Industrial: Eco-friendly alternatives for functional components, housings, and enclosures.

Benefits:

- Environmental Impact: Hemp plastic reduces reliance on fossil fuels and helps mitigate plastic pollution by offering a biodegradable and renewable alternative.

- Brand Image: Using hemp plastic demonstrates a commitment to sustainability and environmental responsibility, enhancing brand reputation and consumer perception.

- Regulatory Compliance: Our hemp plastic materials comply with relevant regulations and standards for biodegradability and compostability, ensuring product safety and compliance.

Why Choose Us?

- Sustainable Solutions: We are committed to sustainability and offer eco-friendly alternatives to traditional plastics, helping our clients reduce their environmental footprint.

- Expertise in Biocomposites: With our knowledge and experience in biocomposite materials, we can develop custom formulations tailored to your specific requirements.

- Quality Assurance: We maintain strict quality control measures to ensure that our hemp plastic components meet the highest standards of quality, performance, and environmental responsibility.

Partner with us for your hemp plastic injection molding needs and join the movement towards sustainable manufacturing. Contact us today to discuss your project requirements or request a quote. Together, we can create eco-friendly solutions that make a positive impact on the planet.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

ISO 9001 Certified Injection Molding Solutions

Read more -

Injection Molding Threads: Precision Threading for Reliable and Functional Parts

Read more -

Customized Injection Molding ABS Plastic Product/Plug/Cover/Caps

Read more -

Discover the Best Injection Molding Company for Your Manufacturing Needs

Read more -

ABS Injection Molding Services

Read more -

LEGO Injection Molding: Precision and Creativity Combined

Read more