Home » Case Products » Hard Plastic Injection Molding

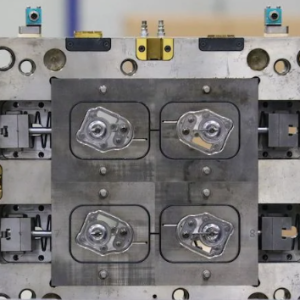

Hard Plastic Injection Molding

In the competitive landscape of manufacturing, precision and efficiency are paramount. Our hard plastic injection molding solutions stand out by offering unparalleled quality and reliability, making them ideal for various industries.

Key Advantages of Hard Plastic Injection Molding

- High Precision and Detail: Our advanced injection molding technology ensures that every product meets exact specifications, reducing waste and enhancing the final product’s quality.

- Rapid Production Rates: With the capability to produce large volumes quickly, our hard plastic injection molding services are designed to meet tight deadlines without compromising on quality.

- Cost-Effectiveness: Our streamlined processes and bulk production capabilities lower costs, making our solutions not only efficient but also economical for your business.

- Versatile Applications: From automotive parts to consumer goods, our hard plastic injection molding can be customized to meet the unique demands of various sectors, providing you with flexibility in product design.

Why Choose Us?

Choosing our hard plastic injection molding services means partnering with a company committed to excellence. We combine state-of-the-art technology with a dedicated team of experts who ensure that every project is executed to the highest standards. Our track record of satisfied clients speaks to our reliability and commitment to customer success.

Contact Us

Ready to elevate your production process? Contact us today to discuss how our hard plastic injection molding solutions can meet your specific needs. Let’s work together to bring your vision to life!

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

ABS Gas Aided with Good Quality in China

Read more -

Rapid Prototyping CNC Machining: High-Precision Prototypes Delivered Fast

Read more -

LSR Injection Molding

Read more -

Transform Your Concepts with Expert Injection Mold Prototypes

Read more -

Custom Automotive Original Plastic Fittings Service

Read more -

Superior Injection Molding Tooling Services at DTG Injection Molding

Read more