Home » Case Products » Expert Injection Mold Design for Precision Manufacturing

Expert Injection Mold Design for Precision Manufacturing

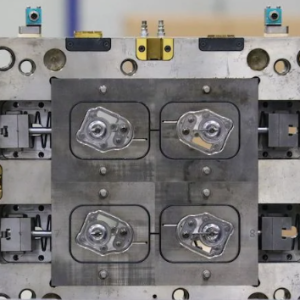

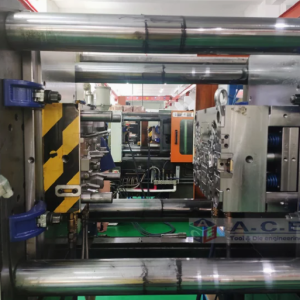

When it comes to injection mold design, precision, efficiency, and innovation are key to producing high-quality parts. At DTG injection molding, we specialize in creating custom mold designs that meet the unique needs of our clients across various industries. Discover why our injection mold design services are the best choice for your manufacturing needs.

Why Choose Our Injection Mold Design Services?

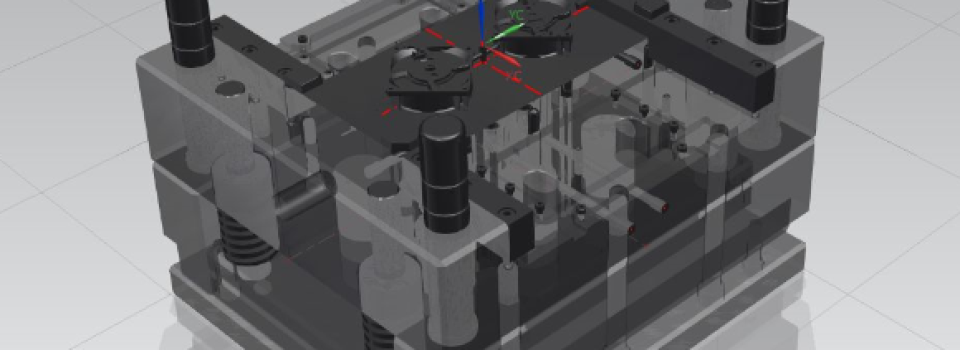

- Advanced Technology: We use the latest CAD/CAM software and simulation tools to design molds with precision and accuracy. Our technology ensures optimal mold performance and reduces the risk of defects.

- Experienced Designers: Our team of skilled designers and engineers has extensive experience in mold design. We understand the complexities of different materials and applications, allowing us to create designs that meet your specific requirements.

- Customized Solutions: Every project is unique, and we provide custom mold designs tailored to your needs. From simple to complex geometries, our designs ensure your products are manufactured to the highest standards.

- Efficiency and Cost Savings: Our designs focus on efficiency, reducing cycle times, and minimizing material waste. This results in significant cost savings and improved productivity for your injection molding operations.

- Quality Assurance: We follow stringent quality control processes to ensure that every mold design meets the highest standards of accuracy and performance. Our commitment to quality ensures your molds deliver consistent results.

Our Injection Mold Design Process

- Concept Development: We begin by understanding your requirements and developing a detailed concept for the mold design. This includes material selection, part geometry, and production volume considerations.

- Design and Simulation: Using advanced CAD/CAM software, we create detailed mold designs and perform simulations to identify potential issues and optimize the design.

- Prototyping: We create prototypes to validate the design and make necessary adjustments. This ensures the final mold meets your exact specifications.

- Production and Testing: Once the design is finalized, we produce the mold and conduct thorough testing to ensure it performs as expected under production conditions.

Industries We Serve

- Automotive: Precision mold designs for components such as dashboards, bumpers, and engine parts.

- Medical: High-quality mold designs for medical devices, surgical instruments, and diagnostic equipment.

- Consumer Goods: Durable and reliable mold designs for electronics, toys, and household items.

- Aerospace: Robust mold designs for lightweight and high-strength aerospace components.

Contact Us for Expert Injection Mold Design

Ready to enhance your production with expert injection mold design? Contact us today to discuss your project requirements and receive a personalized quote. Our dedicated team is committed to delivering exceptional mold designs that meet your needs.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Superior Injection Molding Tooling Services at DTG Injection Molding

Read more -

Innovative Injection Molding Solutions for Custom Plastic Production

Read more -

Custom Plastic Bracelets – Plastic Molding

Read more -

3D Prototyping Service: Fast, Precise, and Cost-Effective Product Development

Read more -

Cheap Plastic Precision Plastic Mould

Read more -

Plastic Shell Electronic Plastic Accessories Factory Custom ABS Plastic Mold Processing

Read more