Home » Case Products » Mastering Draft Angle Injection Molding for Superior Results

Mastering Draft Angle Injection Molding for Superior Results

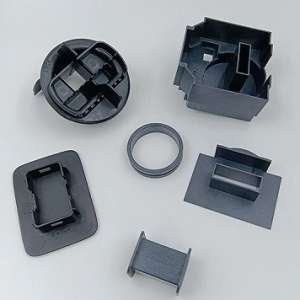

DTG Injection Molding specializes in draft angle injection molding, a critical design element that enhances the efficiency and quality of the molding process. Our expertise ensures that your parts are designed with optimal draft angles, leading to better mold release, reduced wear, and high-quality production outcomes.

Understanding Draft Angle in Injection Molding

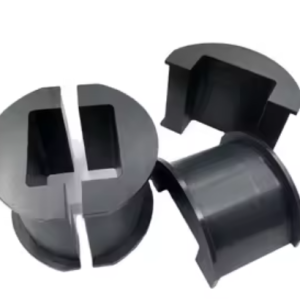

Draft angle refers to the slight taper or slope applied to the vertical walls of a molded part. This design feature facilitates the easy removal of the part from the mold, minimizing the risk of damage and ensuring smooth production.

Benefits of Proper Draft Angle Design

- Enhanced Mold Release

- Overview: Draft angles ease the removal of parts from the mold, reducing the likelihood of sticking or damage.

- Benefits: Minimizes part defects and improves overall production efficiency.

- Reduced Tool Wear

- Overview: Proper draft angles decrease friction between the mold and the part, extending the lifespan of the mold.

- Benefits: Reduces maintenance costs and prolongs the service life of the tooling.

- Improved Surface Finish

- Overview: Draft angles contribute to a smoother surface finish by preventing part distortion and improving mold flow.

- Benefits: Enhances the aesthetic and functional quality of the final product.

- Increased Production Efficiency

- Overview: Parts with optimal draft angles are easier to eject and process, leading to faster cycle times and higher production rates.

- Benefits: Cost-effective manufacturing with improved turnaround times.

Our Draft Angle Injection Molding Services

- Custom Draft Angle Design

- Description: We offer expert design services to incorporate the ideal draft angles for your specific parts and applications.

- Applications: Custom molds, complex parts, and various industries requiring precision and efficiency.

- Design Optimization

- Description: Our team analyzes and optimizes draft angles to ensure that your parts are manufactured with optimal performance and minimal defects.

- Applications: Redesigns for existing molds, new product development, and process improvements.

- Prototyping and Testing

- Description: We provide prototyping services to test and refine draft angles before full-scale production, ensuring the best results.

- Applications: Prototype testing, design validation, and iterative improvements.

- Quality Assurance

- Description: Rigorous quality control processes ensure that all parts meet design specifications and performance standards.

- Applications: Consistent quality checks and detailed inspections throughout the production process.

Industries We Serve

- Consumer Products: Design and production of everyday items with optimized draft angles for enhanced functionality and appearance.

- Automotive: High-precision parts for automotive applications, focusing on durability and performance.

- Medical Devices: Parts requiring strict compliance and high-quality standards, including diagnostic tools and medical equipment.

- Industrial Equipment: Custom components for machinery and industrial applications, ensuring reliability and efficiency.

- Electronics: Parts for electronic devices, designed with draft angles to facilitate smooth manufacturing and assembly.

Why Choose DTG Injection Molding?

- Expert Design Team: Our skilled designers and engineers specialize in optimizing draft angles to enhance mold performance and part quality.

- Advanced Technology: We utilize cutting-edge technology to ensure precise and efficient manufacturing processes.

- Comprehensive Services: From initial design to final production, we provide a full range of services to meet your draft angle needs.

- Cost-Effective Solutions: Our approach ensures high-quality results while keeping production costs manageable.

Get Started with Draft Angle Injection Molding

- Contact Us: Reach out via our online form, email, or phone to discuss your draft angle molding requirements.

- Submit Your Design: Provide your design files and specifications for review and optimization.

- Receive a Quote: We will offer a detailed, competitive quote based on your project needs.

- Begin Production: Once approved, we will start the design and manufacturing process, ensuring high-quality results.

Connect with Us

Ready to optimize your molding process with expert draft angle design? Contact DTG Injection Molding today to discuss your project and receive a prompt, accurate quote. Let us help you achieve superior results with our draft angle injection molding solutions.

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

Thermoset Injection Molding

Read more -

Explore Our Custom Plastic Pokéballs – Plastic Molding

Read more -

Injection Molded Plastic Containers

Read more -

High-Quality Injection Molding Parts from DTG Injection Molding

Read more -

Injection Molding Toys Solutions

Read more -

Urethane Injection Molding

Read more