Home » Case Products » Plastic Injection Blow Molding

Plastic Injection Blow Molding

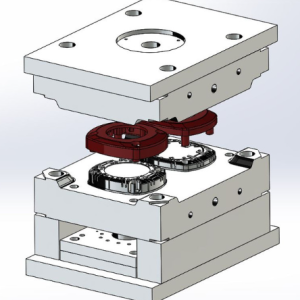

Welcome to our Plastic Injection Blow Molding services, where innovation meets efficiency in producing hollow plastic products with precision and versatility. Injection blow molding is a specialized manufacturing process used to create seamless, hollow plastic parts, such as bottles, containers, and automotive components. Our expertise in this advanced molding technique ensures the production of high-quality, custom-designed products that meet the most demanding specifications.

Key Features:

- Versatility: Injection blow molding allows for the production of a wide range of hollow plastic products, including bottles, containers, jars, and automotive ducts, with intricate shapes and sizes.

- Single-Step Process: Unlike traditional blow molding, which involves two separate steps (extrusion and blowing), injection blow molding combines injection molding and blow molding into a single continuous process, reducing production time and costs.

- Seamless Design: The injection blow molding process produces seamless, uniform products with precise wall thickness, consistent dimensions, and excellent surface finish, eliminating the need for additional finishing operations.

- Material Options: We work with a variety of thermoplastic materials suitable for injection blow molding, including HDPE, LDPE, PP, PET, and PVC, offering flexibility in material selection to meet specific application requirements.

Production Process:

- Injection Molding: The process begins with injection molding, where molten plastic is injected into a pre-formed mold cavity to create a “preform” or “parison” with the desired shape.

- Blow Molding: The preform is transferred to a blow mold cavity, where it is inflated with compressed air or nitrogen to expand and conform to the shape of the mold cavity, forming the final hollow product.

- Cooling and Ejection: After the plastic has cooled and solidified, the mold is opened, and the finished product is ejected from the mold cavity, ready for further processing or assembly.

Applications:

Our Plastic Injection Blow Molding services cater to a variety of industries and applications, including:

- Packaging: Bottles, containers, jars, and jugs for food, beverage, pharmaceutical, and personal care products.

- Automotive: Ducts, hoses, reservoirs, and fluid containers for automotive cooling, fuel, and fluid management systems.

- Industrial: Hollow parts, housings, and enclosures for industrial equipment, machinery, and appliances.

Benefits:

- Design Flexibility: Injection blow molding allows for the production of complex shapes, intricate details, and custom designs to meet specific application requirements.

- Cost-Effectiveness: The single-step process reduces production time, labor costs, and material waste compared to traditional blow molding methods, resulting in overall cost savings.

- High-Quality Products: The seamless design, precise dimensions, and excellent surface finish achieved through injection blow molding ensure the production of high-quality products that meet stringent quality standards.

Why Choose Us:

- Expertise: With years of experience in plastic injection blow molding, we have the knowledge, skills, and resources to deliver exceptional products that meet the most demanding specifications.

- Advanced Technology: Our state-of-the-art injection blow molding machines and tooling are equipped with the latest technology to ensure precise molding, consistent quality, and efficient production.

- Quality Assurance: We adhere to strict quality control measures throughout the manufacturing process to ensure that every product meets the highest standards of performance, reliability, and safety.

Partner with us for your Plastic Injection Blow Molding needs, and let us help you bring your innovative designs to life with high-quality, custom-designed products. Contact us today to discuss your project requirements or request a quote. We look forward to working with you!

Xiamen DTG Injection Molding CO.,LTD

China Manufacturer & Factory

- OEM Services

- Quality Assurance

- R&D Capabilities

DTG Mould Trade Process

| Quote: | According to sample, drawing and specific requirement. |

|---|---|

| Discussion | Mold material, cavity number, price, runner, payment, etc. |

| S/C Signature | Approval for all the items. |

| Advance | Pay 50% by T/T |

| Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Processing | Send report to customer once each week |

| Mold Testing | Send trial samples and try-out report to customer for confirmation |

| Mold Modification | According to customer’s feedback. |

| Balance Settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Injection Molding Quote

Data Privacy And Security:

We Take The Privacy And Security Of Our Customers’ Data Very Seriously, You Upload Product Data Files, We Have Taken Strict Measures To Keep Your Data Safe And Will Not Use It For Any Other Purpose. Your Data Files Will Never Be Forwarded, Sold Or Shared With Other Third Parties.

-

EPDM Injection Molding Solutions

Read more -

Prototype Sheet Metal: Precision Fabrication for Your Custom Designs

Read more -

High-Quality PETG Injection Molding Services from DTG Injection Molding

Read more -

Transform Your Production with Expert Plastic Injection Mold Design

Read more -

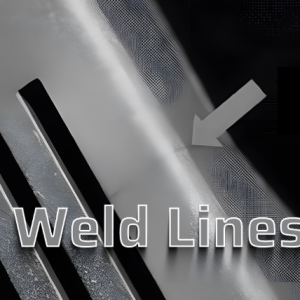

Optimize Your Production with Expert Weld Line Injection Molding Solutions

Read more -

Multi Shot Injection Molding

Read more