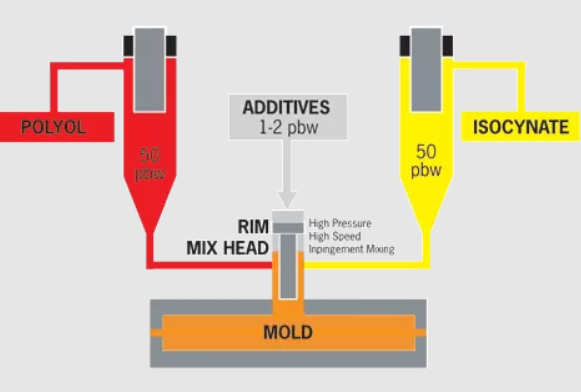

Reaction Injection Molding (RIM) is a manufacturing process used to produce molded plastic parts by mixing two or more liquid…

Blogs

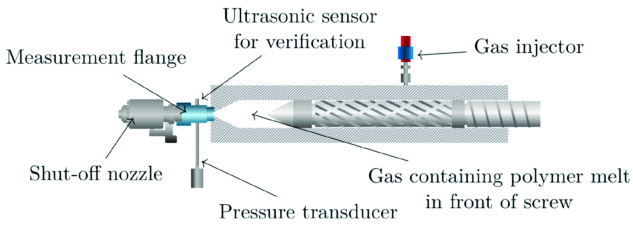

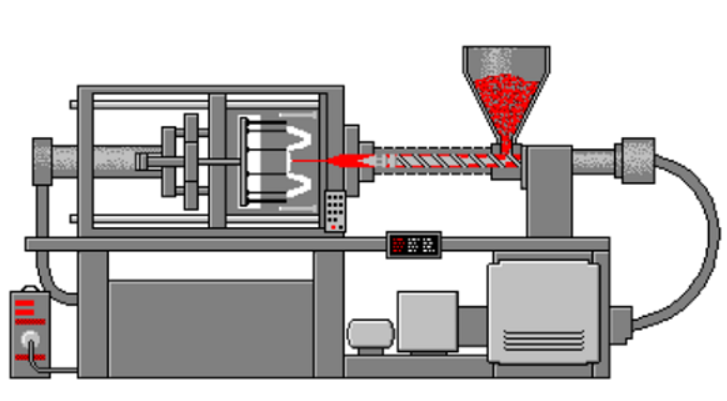

Plasticizing in injection molding is a crucial phase where solid plastic pellets are transformed into a homogeneous molten state, making…

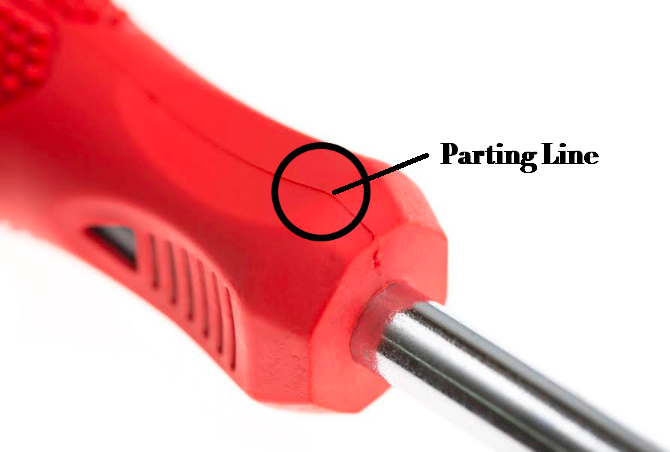

A parting line in injection molding is the line or plane where two or more parts of the mold meet….

Packing pressure in injection molding refers to the pressure applied to the molten plastic after the initial cavity filling phase….

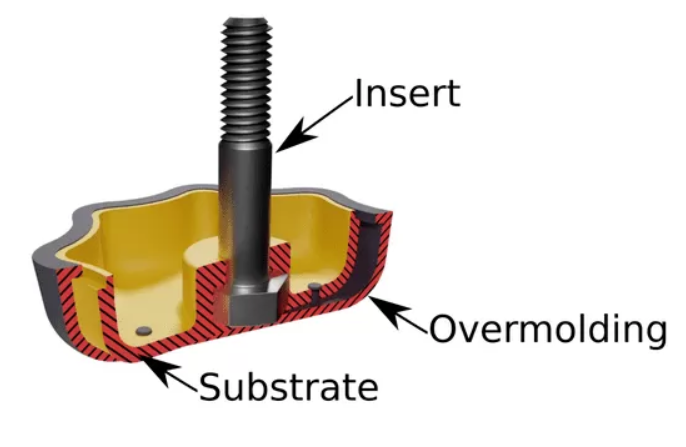

Overmolding is a specialized injection molding process used to create multi-material parts, combining two or more different materials into a…

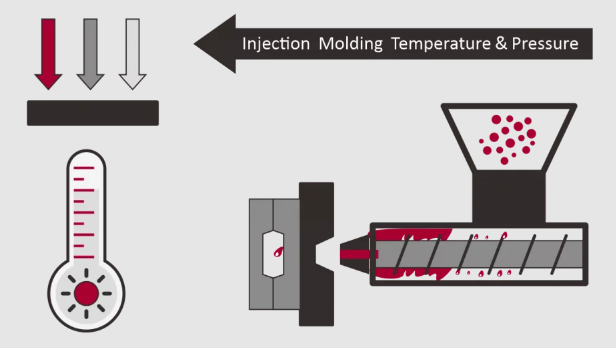

Mold temperature in injection molding refers to the temperature of the mold cavities during the injection molding process. It is…

Micro injection molding is a specialized process within the field of injection molding, designed to produce extremely small and precise…

Melt temperature in injection molding refers to the temperature at which the plastic resin becomes sufficiently fluid for injection into…

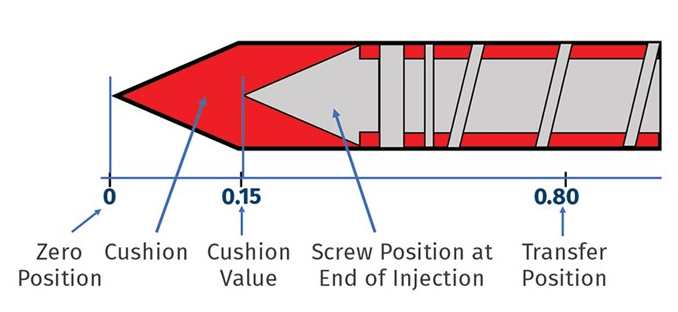

The melt cushion in injection molding refers to the small amount of molten plastic that remains in the barrel of…

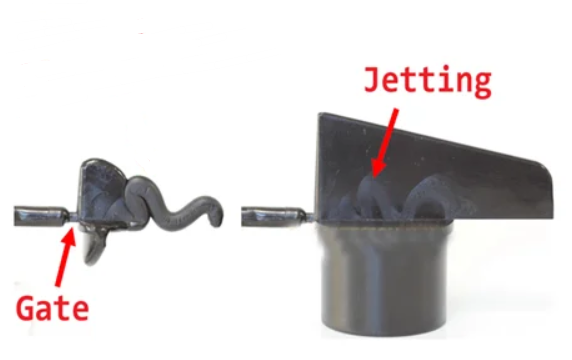

Jetting in injection molding refers to a defect that occurs when the molten plastic enters the mold cavity in a…