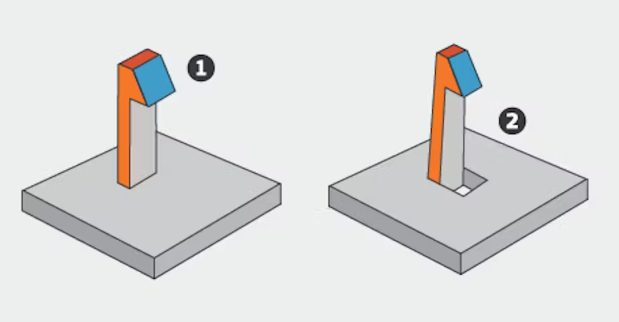

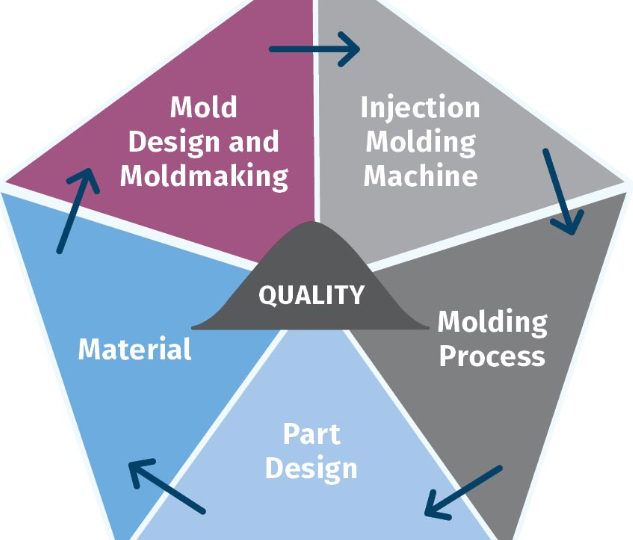

In the world of injection molding, understanding the nuances of part design and mold construction is critical for producing high-quality…

Blogs

In injection molding, tonnage refers to the clamping force exerted by the injection molding machine’s hydraulic system to keep the…

In the realm of injection molding, achieving precise control over the switchover position is crucial for optimizing the production process…

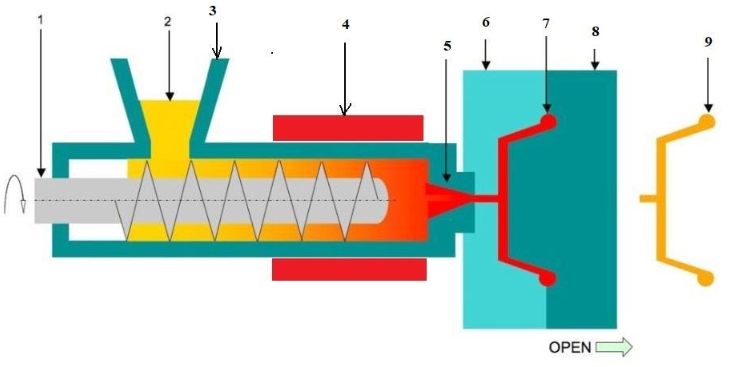

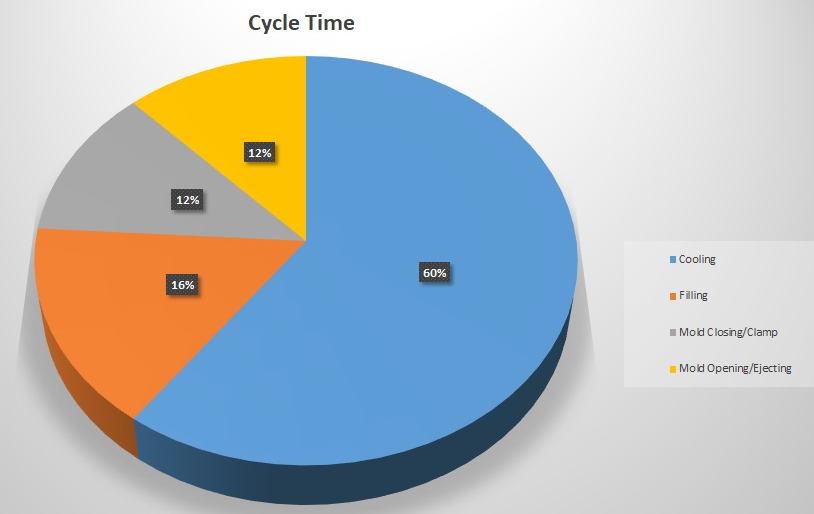

Plastic injection molding is a highly efficient manufacturing process used to produce a wide range of plastic parts. This process…

Calculating clamping force in injection molding is essential to ensure the mold remains closed during the injection process and to…

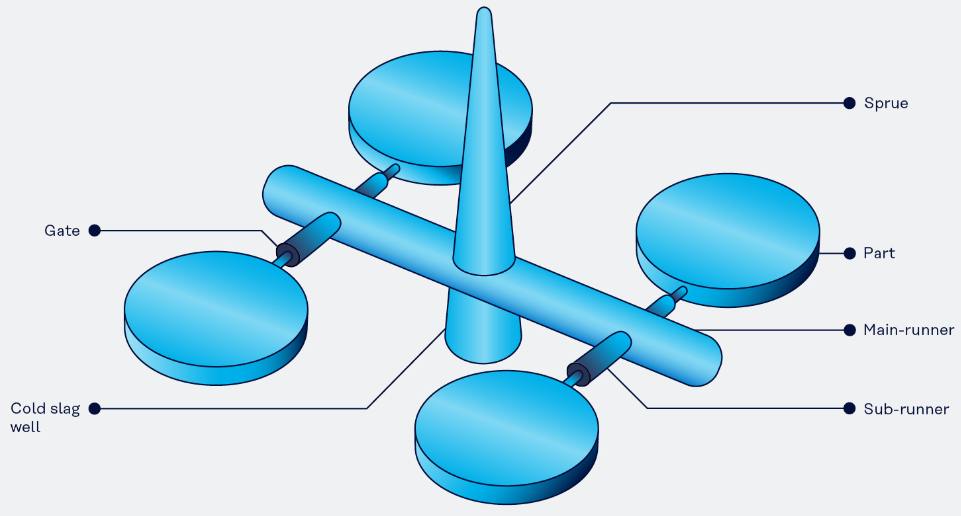

In injection molding, a sprue is the primary channel through which molten plastic flows from the injection molding machine’s nozzle…

In injection molding, shrinkage refers to the reduction in size or dimensions of a plastic part as it cools and…

In injection molding, shear rate refers to the rate at which the material flows and experiences deformation within the mold…

Scientific Injection Molding (SIM), also known as Decoupled Molding, is an advanced injection molding technique that emphasizes the use of…

A runner in injection molding is a channel that guides the molten plastic from the injection molding machine’s nozzle to…