Flow marks, also known as flow lines, are surface defects that appear as streaks or patterns on the molded part….

Blogs

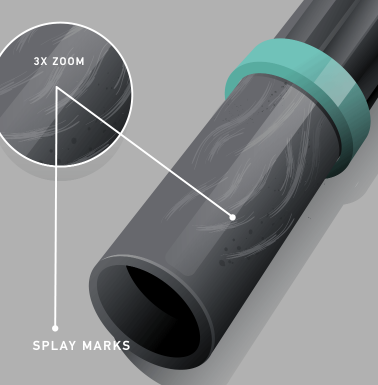

Splay, also known as silver streaking or silvering, is a common defect in injection molding characterized by streaks or lines…

Bubbles, also known as voids or air pockets, are a common defect in injection molding that can affect the quality…

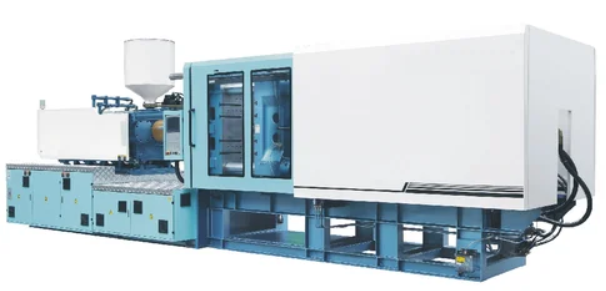

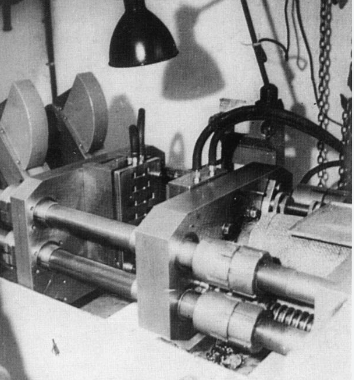

Injection molding machines are essential for producing plastic parts with precision, efficiency, and consistency. Understanding how these machines work can…

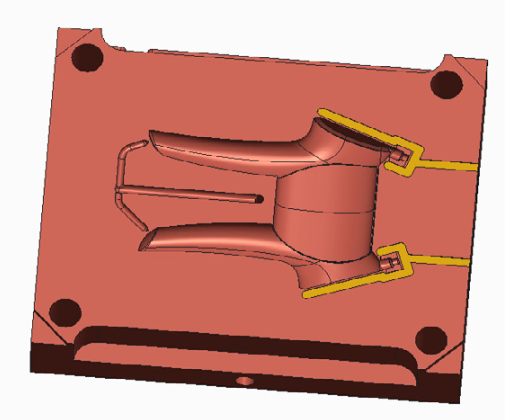

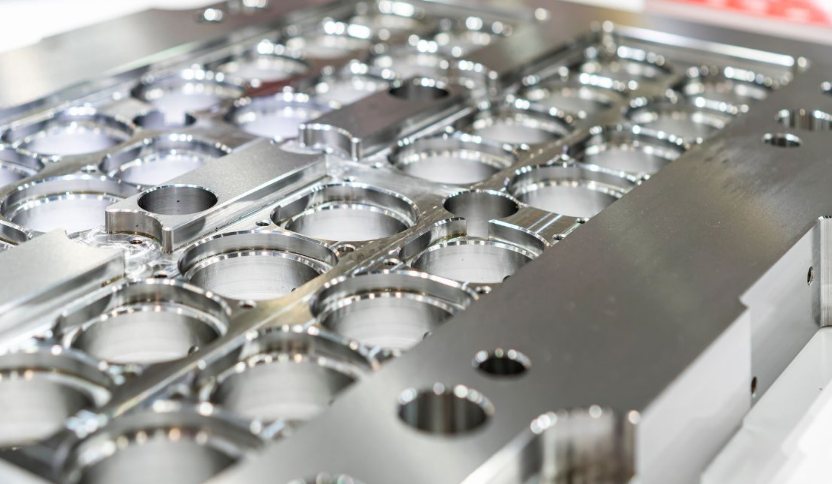

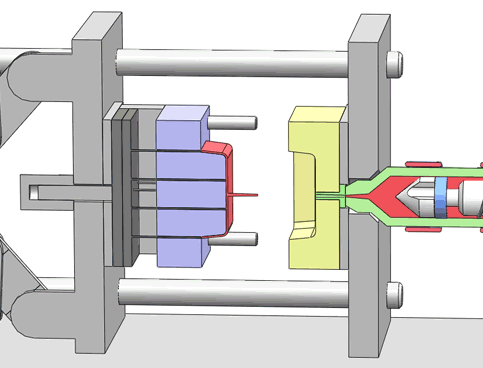

Injection molds are critical tools in the manufacturing industry, enabling the mass production of plastic parts with high precision and…

Ventilation in manufacturing buildings, particularly those that house injection molding operations, is critical for maintaining air quality, ensuring the safety…

Injection molds are essential tools in mass manufacturing, enabling the production of consistent and high-quality plastic parts. The process of…

Ejecting parts from the mold is a critical step in the injection molding process. This step must be performed carefully…

Injection molding, a pivotal manufacturing process in the plastics industry, was invented in 1872 by American inventor John Wesley Hyatt…

Warpage in injection molding is a common defect where a molded part distorts or bends after it has been ejected…