Injection molding machines come in various types, each designed to meet specific production needs and material requirements. Here is an…

Blogs

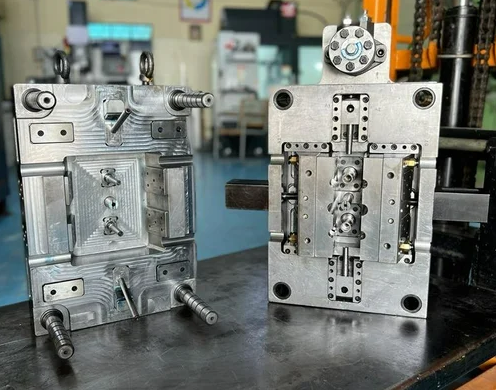

Injection molds are essential tools in the plastic manufacturing process, and they come in various types designed to meet different…

Selecting the right injection molding machine is crucial for ensuring efficient production and high-quality parts. Here’s a detailed guide on…

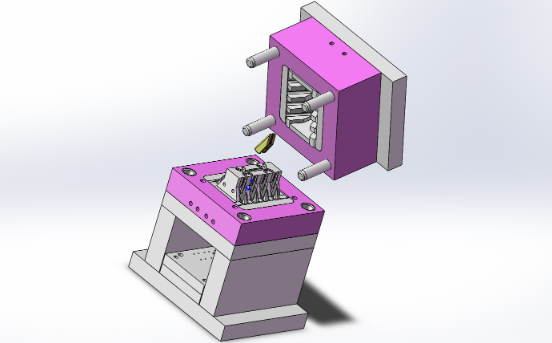

Creating a plastic injection mold in SolidWorks involves several steps, including part design, mold design, and the creation of core…

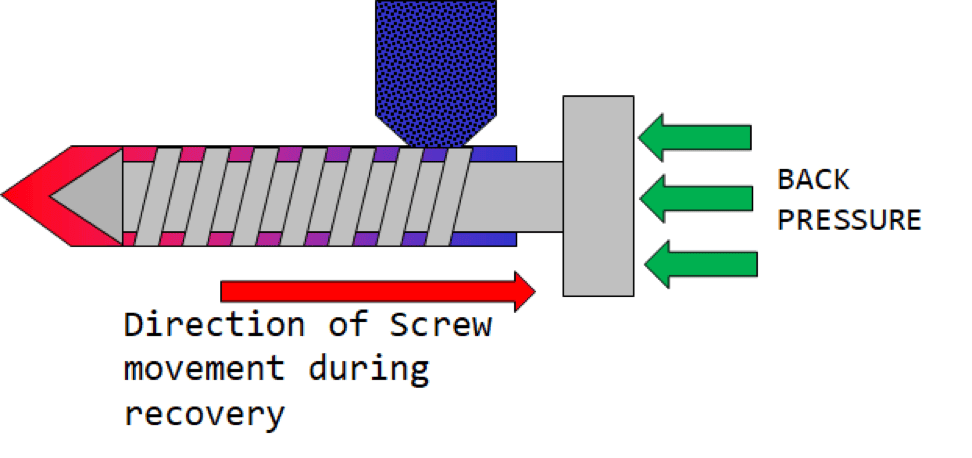

Setting back pressure in injection molding is a critical step to ensure consistent quality and proper plasticizing of the material….

Weld lines, also known as knit lines or flow lines, are surface defects that occur when two or more flow…

Starting an injection molding machine involves a series of steps to ensure that the machine is set up correctly and…

Reducing part weight in injection molding is beneficial for cost savings, material efficiency, and improving product performance. Achieving weight reduction…

Calculating cavity pressure in injection molding is crucial for ensuring the quality and integrity of molded parts. Cavity pressure refers…

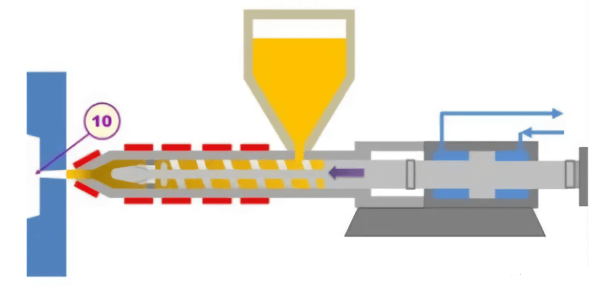

Calculating the barrel capacity of an injection molding machine is crucial for understanding the machine’s ability to handle a specific…